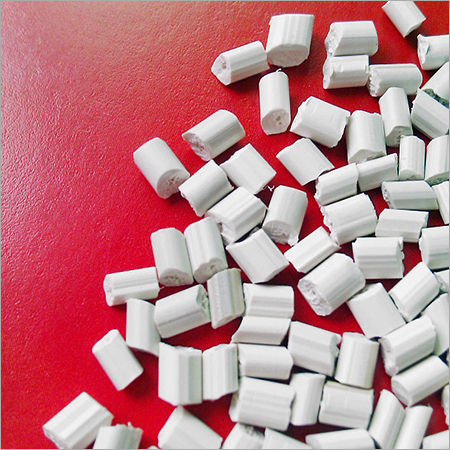

We are one of the most reliable manufacturers and exporters of Non-Woven Color Masterbatches. As an ISO 9001:2000 certified in the industry our range of masterbatches is manufactured using optimum quality material under the guidance of our expert team of professionals. Quality is guaranteed by employing advanced machinery to meet all the requirements of our clients. Our range is characterized for its good filtration performance bright colors and weather resistance. Premium quality material is used in manufacturing Non-Woven Color Masterbatches by utilizing advanced machinery. Other details: Our company uses special processing equipments to do the wet grinding of pigments. Adopting super-dispersant and additives which has good compatibility with polyolefin resins we well coat the pigment particles to achieve good dispersion of high-concentration pigments in the matrix to prevent the condensation of pigment particles caused by the superficial free energy when pigment particles are put thread and to ensure the successful progress of the spinning process and has good spinning performance. About specific criteria please check our corporate standards and product samples. Characteristics The masterbatch products pigment particle size <1m; Distributed evenly stability color strength is high; With excellent filter performance; Polypropylene fiber Masterbatch with a high heat resistance lightfastness. Specification Items Index Apperance Smooth surface uniform grain stain Pigment High concentration easy dispersion high tinting strength ultra-fine degree Additives Compound coupling agent dispersant lubricants anti-aging UV absorbent antioxidant etc. Carrier Fibre grade PP Melting Index (10mm) 15 ~ 40 Filtration-DF Value (barc cm2/g) <0.2 Light Fastness > 5 level Migration Resistance > 4 level Grain Size (mm) 3 x 3mm Spinning Temperature 200 oC ~ 260 oC Suggested Adding Percentage 2.5D silk dosage of 0.5 ~ 3.5% to fully-uniform mixing ApplicationPP filament and staple fiber PP BCF for carpet PP spunbond non-woven fabric.