Plaster Board Production Line (Full Automatic)

Price:

Get Latest Price

In Stock

Product Specifications

| Production Capacity | 10000 Sheets/Day |

| Board Size | 1200*2400Mm |

| Thickness | 9-25Mm |

| Power | 300Kw |

| Weight | 50000Kg |

| Dimensions | 30*15*5M |

| Materials | Steel, Aluminum |

| Features | High Output, Automation, Low Cost, Energy Saving, Easy Operation, High Efficiency, Consistent Quality, Durable, Versatile |

Product Overview

Key Features

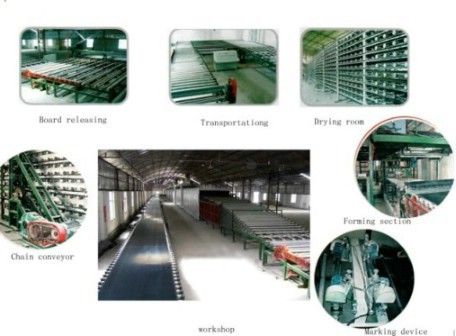

Then the slurry will go into the forming machine and compound with the top and bottom faced paper. By the process of extruding and forming, the slurry will be encased by the faced paper and the continuous pulpous gypsum boards are formed.

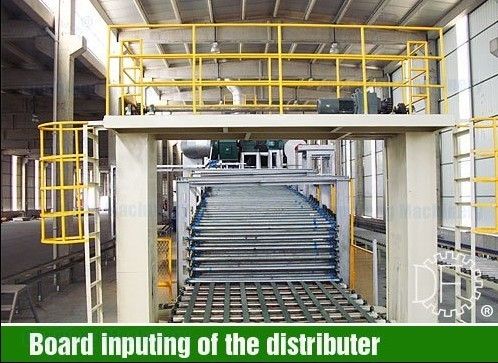

In the forming line, the wet solid paper faced gypsum board will be gradually formed after the process of recondition, natural coagulating, automatic cutting, etc. The wet board will be arranged according to the programmed control system. With the help of rollers, belt conveyer and overturner, they will quickly enter into the dryer.

The board will be strictly controlled in the separate temperature zone of the dryer. After blowing into different thermal hot air, the moisture of the wet board will be evaporated. Because of the reaction of the starch, the board will be attached to the faced paper.

Company Details

Focusing on a customer-centric approach, Yatai Yogncheng Technical Development Co.,LTD has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from Yatai Yogncheng Technical Development Co.,LTD at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

1997

Related Products

Explore Related Categories

Seller Details

Beijing, Beijing

Ms. Wendy Pei

Address

SUNNY CORNER, CHAOYANG, Beijing, Beijing, 100024, China

gypsum board production line in Beijing

Report incorrect details