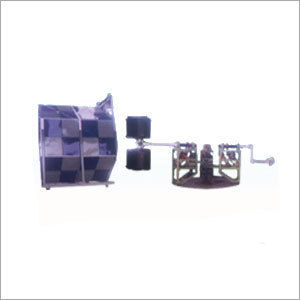

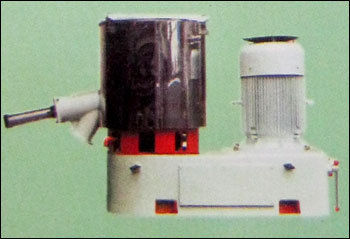

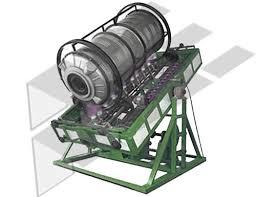

Plastic Granule Making Machine - High-efficiency Polymer Processing, Energy-saving Forced Air Circulation, Bi-axial Rotation For Uniform Heating & Low Cycle Time

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel, Plastic |

| Dimensions | Variable |

| Power | Variable |

| Capacity | Variable |

| Burner | Italian Make |

| Drives | Dc Drives |

| Control | Digital |

| Features | Efficient Energy Use, Uniform Heating, High Production, Lowest Cost, Low Rejection, Environment Friendly, Double Layering, Accurate Speed |

| Payment Terms | Others, Cash Advance (CA) |

| Supply Ability | On Order Per Week |

| Delivery Time | 01 Week |

Product Overview

Key Features

Salient Features:

Most efficient in fuel & energy consumption compared to other types of machines

Uniform heating of the mold with forced air circulation and smooth Bi-axial rotation produce finish product quality

Highest production due to lowest cycle time

Uniform distribution of material hence possible to produce article with lesser weight

Best compatibility in the market due to lowest production cost

Lowest rejection rate due to sound &proven technology

Energy efficient & environment friendly auto system Italian make burner

Flexibility to produce double & triple layer tanks due uniform distribution of material

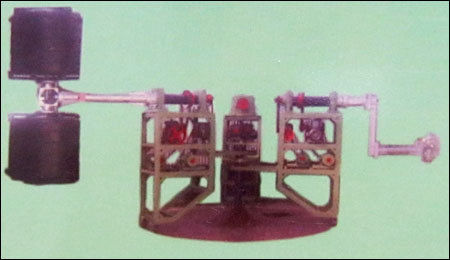

DC drives of reputed make for all minor & major axis's for accurate speed control

Powder coated electrical control panel with dust proof construction & with all switch gears

Control panel is equipped with DC drives, digital indicators, temperature controller, timer & advance automation circuit for entire process control & all necessary safety features

Auto reverse forward panel for minor axis's.

Related Products

More Product From This seller

Company Details

Focusing on a customer-centric approach, NAVDURGA ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plastic Processing Machinery in bulk from NAVDURGA ENGINEERS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

7

Establishment

1995

Working Days

Monday To Sunday

Explore Related Categories

Seller Details

Ahmedabad, Gujarat

Partner

Mr. Nitinbhai Panchal

Address

82, Panchratna Industrial Estate, B/h. Zaveri Estate, Singarva-Kathwada Road, Ahmedabad, Gujarat, 382430, India

plastic granule machines in Ahmedabad

Report incorrect details