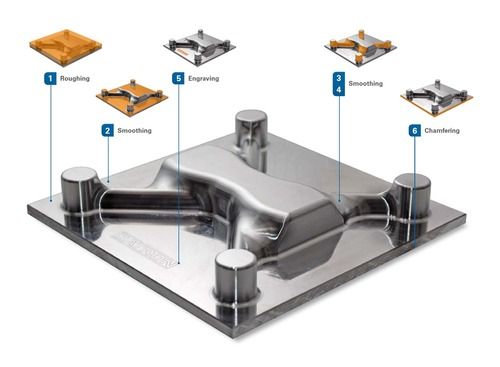

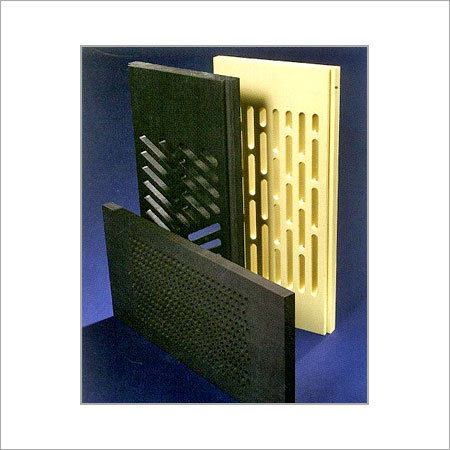

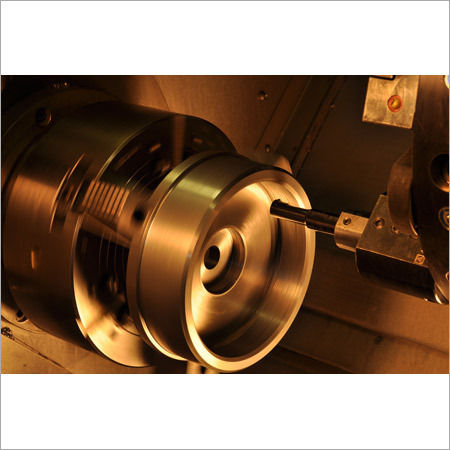

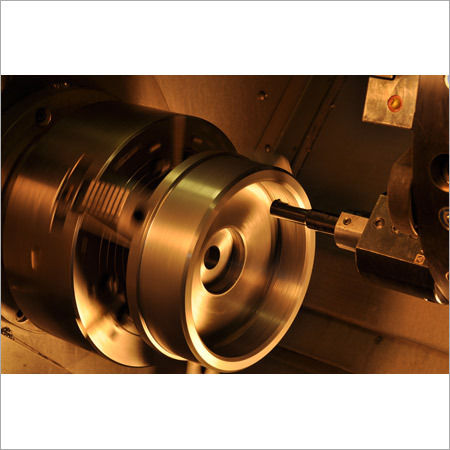

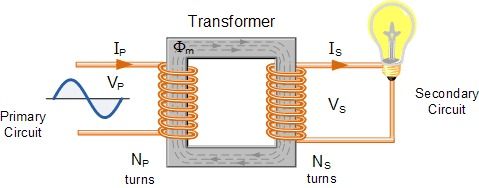

Overview Plastics engineering encompasses the processing, design, development, and manufacture of plastics products. A plastic is a polymeric material that is in a semi-liquid state, having the property of plasticity and exhibiting flow. Plastics engineering encompasses plastics material and plastic machinery. Plastic Machinery is the general term for all types of machinery and devices used in the plastics processing industry.[1] The nature of plastic materials poses unique challenges to an engineer. Mechanical properties of plastics are often difficult to quantify, and the plastics engineer has to design a product that meets certain specifications while keeping costs to a minimum. Other properties that the plastics engineer has to address include: outdoor weather ability, thermal properties such as upper use temperature, electrical properties, barrier properties, and resistance to chemical attack From consumer products to the medical and aerospace industries, plastic and cast parts are critical to successful product designs. SOLIDWORKS provides a set of fully integrated plastic part, cast part, and mold design tools so designers can easily validate that the parts they design can be molded successfully. Tools allow designers to check for draft, thickness, and undercuts to ensure the correct geometry for molding. CNC tech used same software was also includes basic and advanced photorealistic rendering tools to create real-life images of models, including proper texture and translucency.