Polymer Processing Aid Masterbatch - Fluoropolymer Based, Customizable Formulation | Enhanced Extrusion Efficiency, Reduced Melt Fracture, Improved Surface Gloss, Greater Throughput

Price:

Get Latest Price

In Stock

Product Overview

Key Features

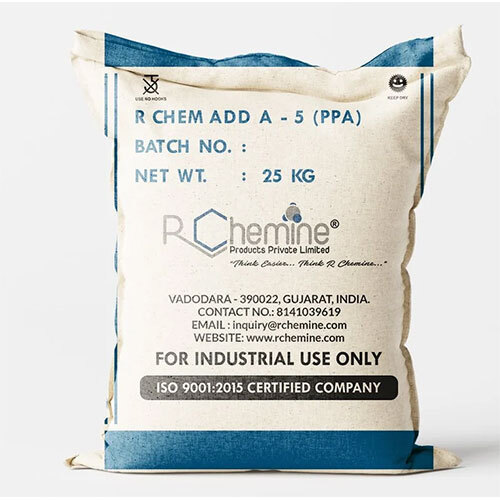

We are identified as one of the leading

organizations, engaged in exporting and supplying Polymer Processing Aid Masterbatch.

Our diligent agents procure this masterbatch from the reputed vendors

of the market. It is specifically designed to enhance extrusion ability

of

plastics such as PE films, pipes and tubes, leading to productivity or

quality

improvement. Polymer Processing Aid Masterbatch is suitable for highly demanding blown film applications such as lamination and surface protection.

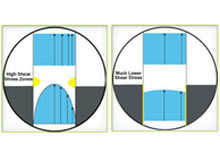

Features:Reduced operating pressuresElimination of melt fracture Improves gloss of final product Polymer Processing Aid (PPA) Masterbatch: Processing issues such as melt fracture at a particular shear rate and die build-up in extrusion processes can be eliminated using processing aids, which help maintain processing continuity and improve throughput. The presence of the lubricating action of processing aids will prevent a slip/ stick action of the molten polymer exiting a die that causes melt fracture and a poor surface finish, occasionally rendering the material unusable. The controlled incompatibility of fluoropolymer based PPAs with the bulk polymer, causes them to rise to the surface, reducing friction at the molten polymer-wall contact. This means a lower head pressure at high shear rates, resulting in better surface finish and higher output, and reduced number of halts for die lip cleaning. What we offer: A range of new generation polymer processing aids pertaining to your choice of polymer and processing method.Masterbatches are available in both, standard and custom-made, forms to best meet your requirements. Carrier Resins: PP, PE and PET Properties Modified: Elimination of melt fracture or shark skin and improved gloss/ clarity of final product.Reduced operating pressures.Reduced variations in thickness profile.Reduced die build up and power requirement.Reduced gel formation and improved gauge control.Significant improvement in throughput and process efficiency. Processing: Blown Film, Cast Film, Lamination, Extrusion (Pipe/ Profile/ Sheet), Blow Moulding, Injection Stretch Blow Moulding, Markets Served: Flexible Packaging Films and Rigid PackagingAgricultural protective filmsDurable Consumer ProductsBuilding/ Construction and LandscapingMedical devices and Healthcare Products","

Normal

0

false

false

false

EN-US

X-NONE

HI

LatentStyleCount=\"267\">

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:\"Table Normal\";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-qformat:yes;

mso-style-parent:\"\";

mso-padding-alt:0cm 5.4pt 0cm 5.4pt;

mso-para-margin-top:0cm;

mso-para-margin-right:0cm;

mso-para-margin-bottom:10.0pt;

mso-para-margin-left:0cm;

line-height:115%;

mso-pagination:widow-orphan;

font-size:11.0pt;

mso-bidi-font-size:10.0pt;

font-family:\"Calibri\",\"sans-serif\";

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-fareast-font-family:\"Times New Roman\";

mso-fareast-theme-font:minor-fareast;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;}

Polymer Processing Aid (PPA) Masterbatch: Processing issues such as melt fracture at a particular shear rate and die build-up in extrusion processes can be eliminated using processing aids, which help maintain processing continuity and improve throughput. The presence of the lubricating action of processing aids will prevent a slip/ stick action of the molten polymer exiting a die that causes melt fracture and a poor surface finish, occasionally rendering the material unusable. The controlled incompatibility of fluoropolymer based PPAs with the bulk polymer, causes them to rise to the surface, reducing friction at the molten polymer-wall contact. This means a lower head pressure at high shear rates, resulting in better surface finish and higher output, and reduced number of halts for die lip cleaning. What we offer: A range of new generation polymer processing aids pertaining to your choice of polymer and processing method.Masterbatches are available in both, standard and custom-made, forms to best meet your requirements. Carrier Resins: PP, PE and PET Properties Modified: Elimination of melt fracture or shark skin and improved gloss/ clarity of final product.Reduced operating pressures.Reduced variations in thickness profile.Reduced die build up and power requirement.Reduced gel formation and improved gauge control.Significant improvement in throughput and process efficiency. Processing: Blown Film, Cast Film, Lamination, Extrusion (Pipe/ Profile/ Sheet), Blow Moulding, Injection Stretch Blow Moulding, Markets Served: Flexible Packaging Films and Rigid PackagingAgricultural protective filmsDurable Consumer ProductsBuilding/ Construction and LandscapingMedical devices and Healthcare Products

"}

Company Details

Focusing on a customer-centric approach, CILANTRO CHEMICALS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Masterbatches in bulk from CILANTRO CHEMICALS PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Importer, Supplier, Trading Company

Employee Count

10

Establishment

2015

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Navi Mumbai, Maharashtra

Accepts only Domestic inquiries

Director

Mr. Sameer Sathe

Address

Office No. 506, JK Chambers, Sector 17, Vashi, Navi Mumbai, Maharashtra, 400703, India

polymer processing aid in Navi Mumbai

Report incorrect details