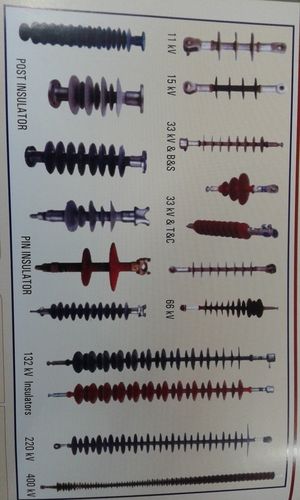

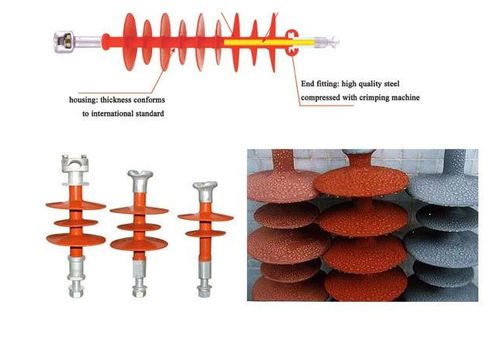

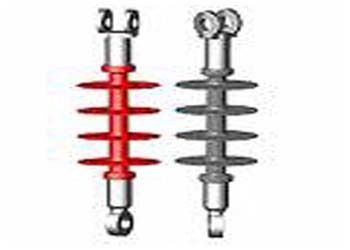

We have successfully manufactured and supplied a wide range of Polymeric Insulators for our customers throughout the country. The offered insulators are precisely manufactured by utilizing quality approved rubber, nylon and other insulating materials with the help most advanced tools and techniques under the supervision of our experienced experts. The provided insulators are used for regulating and controlling the outflow of heat level in the particular medium through pipes, absorbing sheets and insulating rods, demanded in oil, chemical and gas industry. Available at an affordable price range, these Polymeric Insulators can also be custom designed on specific demands of our clients.Features:Strong constructionCorrosion and heat resistanceEasy to installThe exterior appearance of a high-voltage insulator depends on a combination of various factors determining its specific shape. Designing an Insulator for optimum performance requires an exact knowledge and description of all application needs. Polytek Insulator design considers following design criteria to ensure excellent field performance and ZERO DEFECT end product.Mechanical requirementsThe mechanical forces such as bending moments, compression, tension, torsion, etc. acting on the insulator and its connecting system must be accurately specified. Electrical CharacteristicsData such as the lightning impulse flashover voltage, switching impulse flashover voltage and power-frequency flashover voltage define the necessary dielectric strength and insulator length.Creepage distance requirementsCreepage distances are defined in accordance with IEC 60815 and with customers' requirements.Applicable standards and testing codesInternational standards, codes and test specifications are observed in the manufacture of the product. The design comply with IEC 61109 with up dated ammendments. Customer specifications and installation requirementsSpecial requirements (connecting dimensions, diameter, etc.) are considered during design. Environmental conditionsEnvironmental conditions at the installation site determine the design and number of insulator sheds 10 - 15 kv Composite Insulators Nominal pulse System Voltage kV Min. Creepage Distance mm SectionLengthmm RatedMechanicaltensile loadkN Wet power freq. 1 min. withstand voltage kV Dry lightingimpulsewithstandvoltagekV 11 307 274 45 35 75 11 450 430 70 48 100 11 360 330 70 42 100 11 450 430 100 48 100 11 500 430 100 48 100 11 450 430 100 48 100 13 415 341 70 70 100 13 418 360 70 35 100 22 - 28 kv Composite Insulators Nominal pulse System Voltage kV Min. Creepage Distance mm SectionLengthmm RatedMechanicaltensile loadkN Wet power freq. 1 min. withstand voltage kV Dry lightingimpulsewithstandvoltagekV 11 307 274 45 35 75 11 450 430 70 48 100 11 360 330 70 42 100 11 450 430 100 48 100 11 500 430 100 48 100 11 450 430 100 48 100 13 415 341 70 70 100 13 418 360 70 35 100 33 - 36 kv Composite Insulators Nominal pulse System Voltage kV Min. Creepage Distance mm SectionLengthmm RatedMechanicaltensile loadkN Wet power freq. 1 min. withstand voltage kV Dry lightingimpulsewithstandvoltagekV 22 603 425 60 60 140 22 568 333 65 60 140 22 850 444 70 60 140 22 635 444 70 60 140 22 580 349 70 60 140 22 817 397 70 60 100 22 580 349 80 60 140 22 708 365 80 60 140 22 657 378 80 60 160 22 622 458 95 60 160 22 850 444 100 60 140 23 645 442 70 70 204 25 643 451 70 110 200