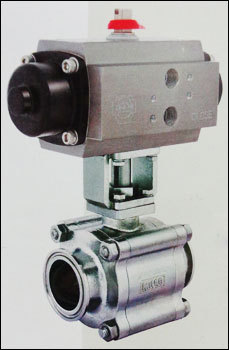

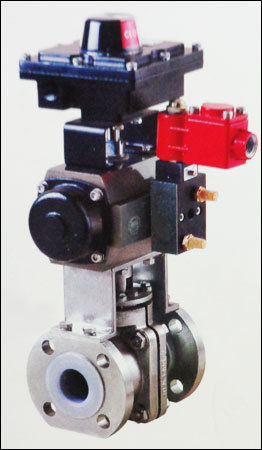

Micro Pneumatics Pvt. Ltd., an indigenous venture commenced operation at Vasai Road in 1986 with pneumatic rotary actuators and later ball valves. Further with the addition of butterfly valves and dampers, Micro Pneumatics Pvt. Ltd. is now also manufacturer of high performance universal wafer butterfly valves in addition to ball valves. These high performance butterfly valves can be installed between any flange standard. High performance butterfly valves include multiple eccentric design, split shaft, aerodynamic slim disc and deflecting, flex rise and fall seat embedded between the body and the retainer. For maintenance, these valves are low down time serviceable as the seat is easily replaceable by just removing the retainer. The disc and the automation remain intact. The process line resultant pressure is nullified and peripherally acting due to disc design and light weight. This enables economic actuator selection. These are comparably low pressure loss butterfly valves. The high performance multi eccentric butterfly valves achieves tight shut-off, vacuum and high gain, full range throttling capabilities. Micro high performance wafer butterfly valves provide long-lasting tight shut-off and a long service life due to non-rubbing of seat placement away from flow. Micro manufactures it's own valves, actuators, solenoid valves and position indicators. Micro Pneumatics Pvt. Ltd. is a single-stop source responsibility. The procurement of valves, actuators and accessories, completely from single-stop source. Valve Capacity Data (USGPM) MICRO Butterfly Valves are designed for optimum capacity of the valve with minimum possible resistance. Valve Size 1.5" 2" 2.5" 3" 4" 5" 6" 8" 10" 12" Cv 82.90 152.50 215.00 312.00 620.00 915.00 1270.00 2295.00 3570.00 5350.00 Valve Torque Data (Kg-M) Micro Butterfly Valves are designed as low torque valves. The torque chart is a guide for actuator selection. Actuator selection to be done consondering factor of safety depending upon service condition, generally selecting a higher size actuator. VALVE SIZE A B C D H H1 L WT.(KGS) 1.5" 42 42 35 52 129 121 200 1.5 2" 45 68 51 60 163 145 250 2.2 2.5" 48 74 60 72 188 165 250 3.2 3" 48 90 72 85 200 170 300 3.8 4" 54 95 100 110 228 195 300 5.5 5" 57 115 123 135 267 220 300 8.0 6" 57 131 143 152 299 235 300 10.0 8" 64 157 192 200 345 250 500 14.5 10" 72 184 239 250 408 301 500 29.0 12" 81 212 290 300 477 350 600 38.0 Lug Type (ANSI 150#) VALVE SIZE A B C D H H1 L N P.C.D L WT.(KGS) 1.5" 42 42 35 52 129 121 200 4 98.40 16 1.75 2" 45 55 45 62 159 141 250 4 120.65 16 2.55 2.5" 48 65 60 76 175 155 250 4 139.70 16 3.75 3" 48 75 75 88 195 165 300 4 152.40 16 4.50 4" 54 97 97 110 230 178 300 8 190.50 16 6.15 Three Piece Screwed / Socket Weld / Butt Weld Ends VALVESIZE A B C D E F G SCH.40 SCH.80 O. D. Wt. kgs RB RB RB I. D. I. D. 15 65 9.0 12.7 74 76 117 117 29 21.8 10 15.8 13.8 21.33 0.5 20 71 14.0 19.0 76 91 117 150 35 27.4 13 20.6 18.9 26.67 0.6 25 94 20.0 25.0 91 97 150 150 43 34.1 13 26.6 24.3 33.27 1.1 32 100 25.0 32.0 97 130 150 250 54 42.7 13 35.0 32.4 42.10 1.7 40 106 32.0 38.0 130 133 250 250 58 49.0 13 40.5 38.1 48.51 2.0 50 115 38.0 50.0 133 160 250 585 71 61.0 16 52.4 49.2 60.45 2.9 80 160 63.0 80.0 167 196 585 737 90.5 102 16 77.9 73.7 88.90 4.2 Bill Of Material COMPONENT MATERIAL Body C I / WCB / CF8 / CF8M Retainer CF8 / CF8M Flap CF8 / CF8M Seat P.T.F.E. D. Shaft Bearing A316 / A304 Shaft Bearing P.T.F.E. Gland Packing P.T.F.E. Gland A304 COMPONENT MATERIAL Gland Follower CF8 / CF8M Bottom Shaft Assembly CF8 / CF8M Shaft Seal P.T.F.E. Lock Pin A304 / A316 Bolts A304 Cap Screws A304 Indicator Plate A304 Handle Assembly Stainless Steel