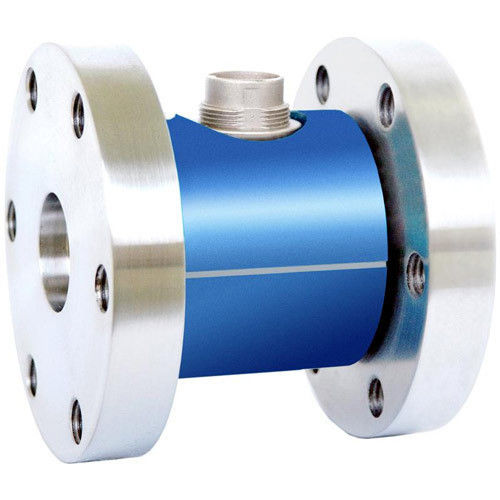

We have achieved an unparalleled name in the market by manufacturing, exporting and supplying premium quality Reaction Torque Sensors. Provided sensors are used to measure the reaction torque of an assembly under test. Offered sensors are manufactured at our highly developed manufacturing unit by our seasoned expert using high quality components procured from authorized vendors of market. Also, proposed sensors are examined on various parameters of quality to ensure a default free range from us. Moreover, these Reaction Torque Sensors are offered to our highly valued clients at the most reasonable prices.Features: No slip rings or bushes Does not change inertia between motor and absorber Usable in any position Withstands large side loads, thrusts and moments No space limitation Usable at zero rpm Mechanical torque overload protection on some models Applications: IEICOS Reaction Torque Sensors measure the reaction torque of an assembly under test. These sensors have no rotating components and hence are used only when the torque sensor experiences no rotating torque. It can still be used to measure torque of rotating machinery in specific applications. They are particularly suited to production applications in which they become an integral part of the system. IEICOS Reaction Torque Sensors are machined as one piece from a solid block. Torque is measured by restraining the case of the test device, and is sensed by strain gauges on torque-sensitive flexures within the structure. No bearings or moving parts are incorporated to cause friction or hysteresis so there is no loss of accuracy at the low end sensors range. Because there are no slip rings or brushes, the sensors may be used when there is no rotation or for applications at any speed, from zero to high as desired with necessary dynamometers or tools. In general, IEICOS Reaction Torque Sensors may be applied where connecting power cables or hydraulic lines do not interfere with reaction torque. However, in some cases where these lines are present, the errors they introduce can be calibrated out by special techniques. The sensor is mounted between the device under test and its normal mount. The torque reacted on the test unit housing produces a slight twist (as low as 0.1o)in the sensor elements. This twist is converted to an electrical signal proportional to torque by means of strain gauges. Readings are not materially effected by bending moments or extraneous loads. The units may be used in any position. The four configurations are available as indicated in figure with one-side shaft, both-side shaft type, flanged type and hollow type. Specifications: Range: 1, 2, 5, 10, 20, 50, 100, 200, 500 & 1000 kgm Sensor: 4 arm bonded strain gauge bridge Bridge resistance: 300 ohms Nominal Bridge voltage: 10 volts DC Linearity: 1% of full scale Overload : 50% of rated capacity