Retort Furnaces - Stainless Steel, Up To 500â°c | Continuous Processing, Controlled Atmosphere, Even Heating, Low Maintenance, Uniform Loading

Price:

Get Latest Price

In Stock

Product Specifications

| product type | Retort Furnaces |

| material | Stainless steel |

| temperature | Up to 500°C |

| rotation | Cantilevered design |

| atmosphere | Controlled |

| loading | Uniform |

| maintenance | Low |

| Features | Even Heating, Controlled Atmosphere, Continuous Processing, Uniform Loading, Low Maintenance |

Product Overview

Key Features

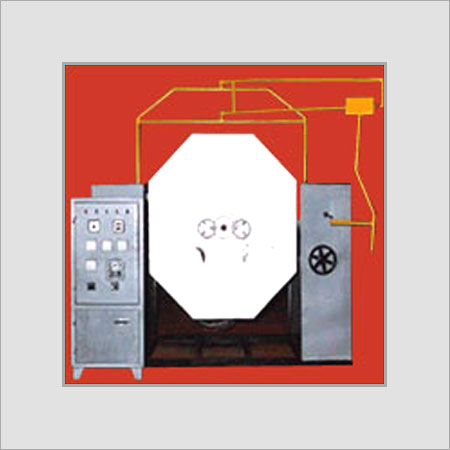

Have long been used for the continuous heat treatment of a variety of raw materials. The rotary retort furnaces is particularly adaptable to controlled atmosphere operation up to 500A c. These furnaces are particularly well suited for the processing of raw materials because the rotary conveying action tumbles the materials, breaking up any jams or tangled clumps facilitating more thorough heat treatment of each of the individual part. The traditional rotary retort concept is not without problems improper and uneven loading, jams of parts formed at the charge end that cannot be broken up in the retort, the maintenance of rotary bearing and seals within the heated shell and the loss of controlled atmosphere.

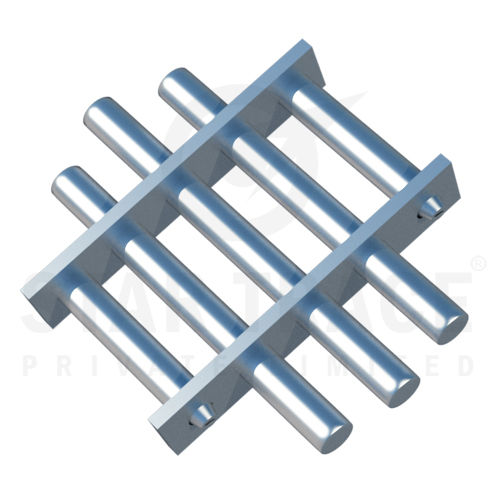

The rotary retort has a charging door mechanism that works with a loading mechanism to load controlled, pre-selected weight charges of uniform size parts into the retort, minimizing the loss of any controlled atmosphere. Cantilevered retort design the stainless steel retort is supported for rotation at only one end, outside of the shell, such that the retort is cantilevered into the shell with the free end extending into the furnace shell. This design requires less maintenance and is more efficient at conserving controlled atmosphere than designs with internal rotation within the heated shell.

Company Details

Focusing on a customer-centric approach, STAR TRACE PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Furnace Manufacturers in bulk from STAR TRACE PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

60

Establishment

1991

Working Days

Monday To Sunday

GST NO

33AAGCS1572A1ZU

Certification

ISO 9001-2000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33AAGCS1572A1ZU

Chennai, Tamil Nadu

Managing Director

Mr. P. R. Maheswaran

Address

Old No. 7, New No. 5, Jeevanandam Street, Red Hills, Chennai, Tamil Nadu, 600052, India

retort furnaces in Chennai

Report incorrect details