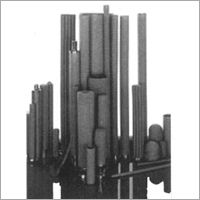

We have marked a distinguished position in the domain by manufacturing and exporting a broad assortment of Reusable Filter Element. Offered filter element is commonly used for high temperature and high pressure filtration purposes. Manufactured in our advanced manufacturing unit by making use of quality approved stainless steel in conformity with international quality standards, provided filter element is tested on various quality parameters. In addition, this Reusable Filter Element can be availed from us in varied technical specifications. Features: Sturdy construction Excellent filtration Perfect finish Easy installation Specifications:Reusable Series elements are designed for use in standard commercially available Filter Housing. Absolute particle retention is offered while providing the low initial differential pressure unique to a pleated elements. The elements have a high surface area for greater dirt holding capacity and longer on stream life. Maximum differential pressure in the forward direction is 300 psid at 450F. The double open end and other various end design allows installation in most commercial filter vessels. Nominal 10, 20, 30 or 40 inch lengths are available. Special Jumbo type Filter Cartridges are also available.Material of Construction Media: SS 316L Multilayered Mesh Upstream Support: S.S. 316 Downstream Support: S.S. 316 Core: S.S. 316 Sleeve: S.S. 316 End Caps: S.S. 316 Micron Ratings0.5, 1.0, 3.0 5.0, 10, 20, 40, 60 and 75 micron liquid particle retention is typically 98.0% efficient at the stipulated pore size.Maximum Differential Pressure Forward: 250 psid @ 700F Backward: 50 psid @ 700F Filtration Area 0.3 sq. meter per nominal 10 inch (25cm.) cartridge CleaningThe ideal application use a solvent compatible with Stainless Steel that will dissolve the contaminant, insoluble contaminants may be removed by back flushing. Application cleaning procedures are specific to the contaminants. May be cleaned chemically, Mechanically or thermally. Contact Finix Filters for further information about the process.Filter Housing A complete line of Stainless Steel filter vessels is available from Finix Filters. This include single element, low pressure multi cartridge ASME Code and high pressure ASME code vessels.SealsEPDM, Silicone, Viton or PTFE are offered for this service.The media is entirely 316 grade stainless steel. End caps and core are 316 stainless steel and are welded to the metal mesh. All components are in compliance with applicable FDA regulations. Typical Applications Advantages Spargers 304 or 316 stainless steel. Cyrogenics Fabrication is by welding and crimping, no adhesives or epoxy bonding. Beverage Filtration Superior Chemical compatibility. Highly Viscous Fluids Excellent mechanical strength Corrosive liquids & Gases Cleanable & Reusable Super Heated Process Steam Element Surfaces can be plain cylindrical or pleated to increase filter surface area. High Temperature Processing Recovery Of Valuable Particulate Catalyst Recovery