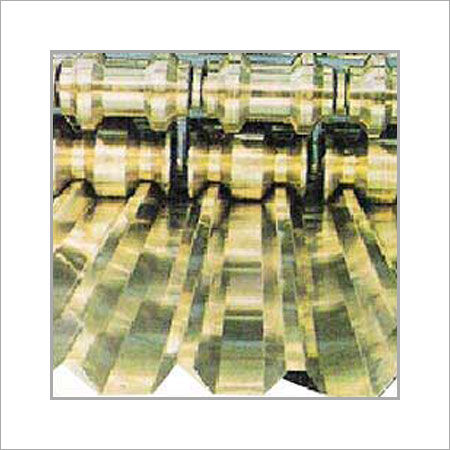

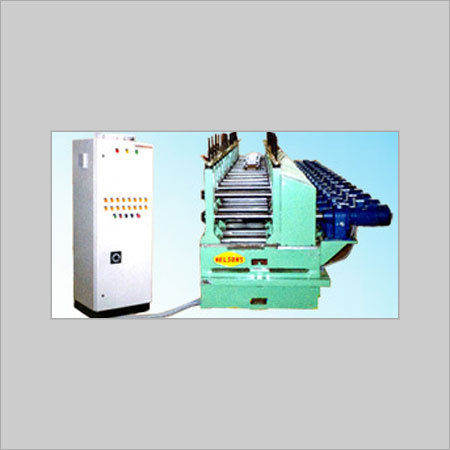

Products DescriptionSavany profile roll forming system is a high-quality product specifically designed to meetthe production schedules and expectations of customers in the construction industry. This production line, with its array of functions and advantages, is an ideal choice for businesses of all sizes. Beyond its application in the construction sector, the Savany Roll Forming Production Lineis also widely used in electrical engineering, home appliances and furniture, logistics and transportation, as well as in the automotive and ship industries. The Panel Roll Forming Machine can efficiently produce various specifications of metal profiles, such as ceilings, roof tiles, shelf decking, electrical cabinet enclosures, storage cabinet mounting plates, decorative panels, andmore. Savany also offers highly flexible and customizable solutions for roll forming processes.Composition of Rolling Forming System(1)Roll forming machine(2)Unpowered roller feeder(3)Small electric uncoiler with manual tensioning, auto decoiler with coil car, hydraulic uncoiler (Option)(4)PLC control system(5)Cutter(back-front cutting system or slitting line cutting machine)(6)Punching machine(7)Frame(8)Material transfer system or manipulate stamping handing robot conveyance system (OptionEquipment structure and performance introductionUncoiler: the material width is customized according to the customer's product unfolding sizeaccommodating various materials and thicknesses. the coil inner diameter ranges from 450-520mm,with a maximum outer diameter of 1300mm.Punching Machine: Adopting hydraulic mold frame, the size of punching pressure is designedaccording to the products required, the power of the mold frame is driven by hydraulic pressure,the size of the cylinder is matched according to the punching force required by the actualproducts, and the punching speed is about 2 seconds/times.Roll Forming Machine: lt adopts the cold bending forming method. the roller material is Cr12MoV,which undergoes rough machining followed by vacuum heat treatment to achieve a hardness ofHRC58-62. the two end faces and inner bore are precision ground, and keyways are cut by wireelectrical discharge machining (WEDM). Finally, it is precision-machined to the designdimensions using Japanese CNC lathes, with optical inspection ensuring consistency betweenthe processed parts and the design drawings. The spindle and side plates: The spindle material is40Cr, which undergoes rough machining followed by quenching and tempering. it is thenprecision-machined using imported CNC lathes and finally ground on a cylindrical grindingmachine for all dimensional accuracy. Each spindle is equipped with three sets of Harbincylindrical or conical bearings. The side plates are all made of Q235 steel plate, with the mainside plate thickness of 36mm and the auxiliary side plate thickness of 28mm. They are allprocessed and formed in one operation using precision CNC machining centers, and all surfacesare treated with baking paint or electrophoresis. Gear transmission is used between the rollers,with the motor directly driving the reducer. The main machine is driven by one reducer, and the rollforming speed is up to 12 meters per minute.Control System: lt adopts touch-screen human-machine interface (HMl) operation and PLCprogram intelligent programming control. the control console is installed in a convenientoperating position. the control cabinet wiring output adopts aviation plug connections. lt has anindependent count-holding function, allowing operators to easily view the work records of the day.the mechanical movement mechanism is suitable for human operation and is designed withsafety protective covers and interlocking protection mechanisms. the electrical control wiring isnot qrounded or exposed.BenefitsSavany can customize high-quality machinery according to your requirements and provide youwith a variety of satisfactory solutions.The fully automatic roll forming production line can produce metal profile of differentspecifications, with product diameter and length being easily switched via a touchscreen with asingle click.The automated production process enhances production efficiency, reduces scrap rates, andsaves significant investment costs and foor space for users.Savany's roll-formin line is simple and convenient to operate, with processes such as cuttingpunching, bending, and forming completed in a single pass.The rolling system operates with low noise, high efficiency, and a long service life.The critical components of the equipment are all manufactured using parts from well-known brands, effectively ensuring the performance of the equipment.If your profile production does not require a high-performance system, we can provide you with aparticularly economical standard system to meet the requirements of lower output or change over times.We believe that Savany pannel roll forming line offers an unbeatable combination of quality,performance, and value. lf you have any questions about this product or would like to learn moreabout how it can benefit your business, please don't hesitate to contact us. We are dedicated toproviding excellent customer service and helping our customers achieve their business goals.Thank you for considering Savany pannel rolling forming production line. We look forward to theopportunity to work with you and help you achieve success.