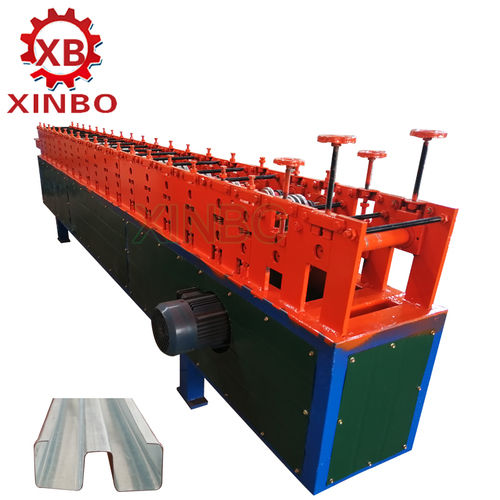

Rolling Door Making Machine

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Steel |

| Dimension | 6.5M*1.5M*1.4M |

| Motor Power | 4Kw |

| Hydraulic Power | 4Kw |

| Material Thickness | 0.3-1.0Mm |

| Roller Material | 45# Steel |

| Control System | Plc |

| Features | High Speed, Durable, Precise Cuts, Easy Operation, Rust Resistant, Cost Effective, Versatile, Strong Output |

| FOB Port | Tianjin |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID) |

| Supply Ability | 30 Per Month |

| Delivery Time | 35 Days |

| Packaging Details | standard package |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia |

Product Overview

Key Features

Product Applicationi

This Iron Steel Rolling Shutter Door Slats Roll Forming Machine Prices line uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate. The products produced by this Iron Steel Rolling Shutter Door Slats Roll Forming Machine Prices are bright in colored, against fading, resistant to rust, and be widely used in shops, working departments, warehouses, and fire partition. Its strength is three times higher than aluminum alloy door.

Technological processi

Uncoiler-Feeding-Leveling-hydraulic punching-Hydraulic cutting-Roll forming-Output table

Technical parameteri

1.Suitable materialColor steel sheet, galvanized steel sheet, aluminum sheet

2.Installation Dimension (L*W*H): 6.5m*1.5m*1.4m

3.Main motor power : 4KW with Cycloidal reducer

4.Hydraulic station power : 4KW

5. Hydraulic oil pump : CB-E 310

6.Thickness of material : 0.3mm~1.0mm

7.Diameter of principal axis : I 70-90mm

8.Material expand width : 1000-1250mm

9.Electric tension : 380V 3phase 50HZ or as the customer's requirements

10.Material of roller : High grade 45# forged steel plated with hard chrome plating

11.Controlling system : PLC

12.Processing speed : 8-12m/min(glazed tile is 2-3m/min)

13.Processing precision within : 1.00mm (depend on design)

14.Material of cutting blade : Cr12 mould steel with quenched treatment

15.Kind of drive : 0.6 inch chain link bearing model 6210

16.Roller station : 11-20 Rollers

17.Roller material : high grade 45#steel; Cr12 quenching

18. Leak frame load-bearing : 4.6T

Rollers

In order to get high quality product, our machine adopts welded steel frame structure, AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating.

Roller Station:11-18rows

Or custome an customer's requirements Thickness of feeding materiali 0.3-0.8mm

Computer Control Cabinet

It adopts MITSUBISHI PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

Hydraulic Station

It is derived by a Gear Pump. After filling the hydraulic oil into the hydraulic oil tank, the pump could drive the hydraulic cylinder to realize the cutting function.The system includes a set of hydraulic tank, a set of a Gear Pump, two hydraulic pipes .and two sets of Solenoid Valves.

Power of The Pump:4kw

Hydraulic oil :40#

Company Details

Business Type

Supplier

Employee Count

20

Establishment

2015

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Botou, Hebei

Mrs Serena Xin

Address

No.104, national road, Botou, Hebei, 062150, China

roof forming machine in Botou

Report incorrect details