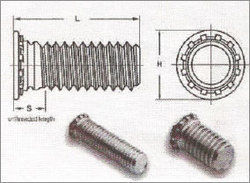

By keeping track of the latest market developments, we are involved in manufacturing, exporting and supplying Self Clinching Stud. Provided stud is basically a threaded insert that is pressed into moulded components with pre-punched receiving holes, thereby making a permanent connection. Offered stud is manufactured using supreme grade steel and cutting-edge technology in tandem with set industry standards. In order to meet the varied needs of our clients, we are offering this Self Clinching Stud in various sizes, designs and other specifications at cost effective price. Features: Resistant to corrosion Quick installation High torque and pull out strength Withstand high loads Description:KALYANI SALES CORPORATION offers Self Clinching Studs which are threaded inserts made of steel with a specially formed head. They are used in thin walled moulded components made of steel, light alloy, NF metal. During this process, the material flows out of the area of the hole wall into the annular grooves of the Self Clinching Studs thereby making a permanent connection. Self Clinching Stud is designed to provide wear free screw connection capable of withstanding high loads in thin walled moulded components from 1.0 mm thickness & above. Self Clinching Studs have distinct advantages like: easy & quick installation; high torque & pull out strength; can be used in surface treated, ready plated parts, minimal outside dimensions for space and weight saving designs with an aesthetic look. Self Clinching Studs are used in various applications such as Sheet Metal Control Panels, PCBs, UPS, Invertors, Household appliances, Medical & Pharmaceutical equipments, etc. Self Clinching Studs are available in sizes from M2.5 to M8 and length from 6.0 mm to 60 mm. They are available in materials like Steel Hardened, Steel Unhardened, Stainless Steel and Aluminum. KFH(Flush Head) studs are installed by placing them in punched or drilled holes in the sheets and squeezing in to place with any standard prices. The squeezing action embeds the head of the stud in to the sheet. The metal displaced by the head flows smoothly and evenly around the ribs and in to the annular groove- creating a flush head assembly and securely locking the stud in to the sheet with high torque out ad push out resistances. Other types such as unthreaded, KTFH(Non Flush) studs & KHFH(High strength) studs are also available on special order.All Dimensions are in millimeters Metric Thread Size x Pitch Type Thread Code Length Code "L" + 0.4 (Length Code in Millimeters ) Min. Sheet Thickness Hole Size in Sheet +0.08 Max. Hole in Attach Parts H + 0.4 S Max Min. Dist. Hole C/L to Edge Fastener Material Steel Stainless Steel Aluminum M2.5 x 0.45 KFH KFHS KFHA M2.5 6 8 10 12 15 18 NA NA NA NA 1 2.5 3.1 4.1 1.98 5.4 M3 x 0.5 KFH KFHS KFHA M3 6 8 10 12 15 18 20 25 NA NA 1 3 3.6 4.6 2.1 5.6 M3.5 x 0.6 KFH KFHS KFHA M3.5 6 8 10 12 15 18 20 25 30 NA 1 3.5 4.1 5.3 2.25 6.4 M4 x 0.7 KFH KFHS KFHA M4 6 8 10 12 15 18 20 25 30 35 1 4 4.6 5.9 2.4 7.2 M5 x 0.8 KFH KFHS KFHA M5 NA 8 10 12 15 18 20 25 30 35 1 5 5.6 6.5 2.7 7.2 M6 x 1 KFH KFHS KFHA M6 NA NA 10 12 15 18 20 25 30 35 1.6 6 6.6 8.2 3 7.9 M8 x 1.25 KFH KFHS KFHA M8 NA NA NA 12 15 18 20 25 30 35 2.4 8 8.6 9.6 3.7 9.6