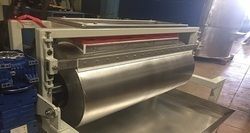

Semi Automatic Plate Rolling Machine - Heavy Duty Design, 12x2500 Mm, 4 Mtr/min Max Speed, Tube & Round Bar Shaping, Perfect For Petroleum And Chemical Industries

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Cast Steel |

| Dimensions | 12X2500 |

| Rollers | 3 |

| Capacity | 15-20 Ton/Day |

| Speed | 4 M/Min |

| Type | Cold Rolling |

| Grade | Semi-Automatic |

| Features | Precise Bending, Durable Design, High Capacity, Versatile Use, Easy Operation, Efficient Rolling, Cost Effective |

| Payment Terms | Others, Telegraphic Transfer (T/T) |

| Delivery Time | 2 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | Tamil Nadu |

Product Overview

Key Features

Product Details:-

Minimum Order Quantity1 Piece

Automatic GradeAutomatic, Semi-Automatic, Manual

Rolled ShapeTube, Round Bar

Production Capacity15-20 ton/day

Machine TypeCold Rolling Mill

Max Rolling Speed (metres/min)4mtr/min

The feature of heavy duty plate rolling machine roller machine

The machine widely used in petroleum, chemical industry, cement, bioler, shipbuilding, aviation, water conservancy, power transmission towers and other machineary and equipment. Its working principle is rotating bending deformation. For the upper roller can be woved no matter up and down, but also horizontally, so no need additional press or equipment, can realize bending, as well as correction of the workpiece.

The whole structure of W11 12x2500 heavy duty plate rolling machine roller machine

1.The machine adopts 3-roller symmetrical structure with the upper roller moving vertically in the center between the lower rollers, wihch is achieved through the drive of the screw, the unt, the worm and the lead screw.

2.The two lower rollers rotates, and privideds the plate materials with torque through the engagement of the output gear of the moderator with the gear of the lower rollers.

3.Adapted for benidng metal plate into round, arc, and so on. Its working principle is ratary benidng deformation. This product is widely used in chemical industry, cement, shipbuilding, boiller, aviation, water control project, power transmission tower, metal structure and the industry of making machinery.

Major parts of the manufacturing process

1.Working rollers: cast steel ingot(chemical composition analysis):check performance-forging roughcast-forging annealing-UT flaw-roughing(chemical tests)-heat treatment(hardening and tempering)-UT flaw-semi finishing-finishing-MT

2.Large forigings: cylinder body, gear, gear shaft forging roughcast-surface imspection-roughing-UT flaw-UT flwa detector hear treatmenat-finishing semi-finishing-MT

3.Welding structure: racks, chassis, wheel box plate into the factory(chemical compositon analysis, mechanical test)-pretreatment-for sheet metal cutting-welding-seam UT or RT flaw-annealing treatment-roughing-finishing-vibration destressing-hot blasting-finishing 5-4 major parts of the manufacturing process.

Company Details

Focusing on a customer-centric approach, Suresh Fabricators & Contractors has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Machinery & Parts in bulk from Suresh Fabricators & Contractors at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Salem, Tamil Nadu

Proprietor

Mr Suresh Varunadevan

Address

109, Mottur, Gonur Post, Mettur Dam, Salem, Tamil Nadu, 636404, India

plate rolling machine in Salem

Report incorrect details