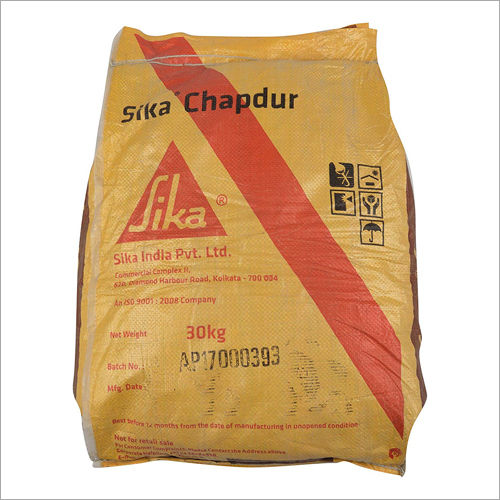

Sika Chapdur Floor Hardener

Price: 150 INR / Kilograms

Get Latest Price

Minimum Order Quantity :

10 Kilograms

Brand Name :

Sika

In Stock

Product Specifications

| Usage | Construction Purpose |

| Application | Industrial and Commercial |

| Purity | 98%-99% |

| Feature | Good Quality |

| Physical Form | Powder |

| Grade | Chemical |

| Appearance | Natural (Concrete grey) |

| Payment Terms | Cash Advance (CA), Cheque, Others |

| Supply Ability | 150-200 Per Month |

| Delivery Time | 5 Days |

| Packaging Details | 30 kg bags |

| Main Domestic Market | Maharashtra |

Company Details

Business Type

Service Provider, Supplier, Trading Company

Employee Count

10

Establishment

2019

Working Days

Monday To Saturday

GST NO

27BPYPS9053M2ZK

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA)

Related Products

Explore Related Categories

Seller Details

GST - 27BPYPS9053M2ZK

Pune, Maharashtra

Accepts only Domestic inquiries

Proprietor

Mr. Sanjay Shinde

Address

Building No. B1, Ranakpur Nagri Society, Pimple Nilakh, Aundh Camp Pune, Maharashtra, 411027, India

Report incorrect details