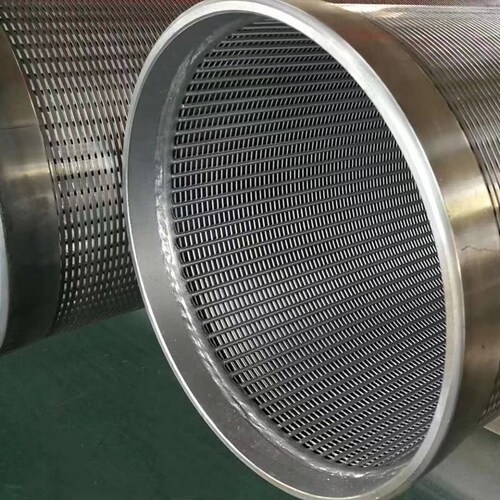

Stainless Steel Wedge Wire Screen Static Sieve Bend Filters

Price: 80 USD / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Specifications

| Usage | Waste Water Treatment |

| Size | Customized |

| Capacity | 10 m3/hr |

| Height | Customized Millimeter (mm) |

| Weight | 20 Kilograms (kg) |

| Width | Customized Millimeter (mm) |

| Length | Customized Millimeter (mm) |

| Color | Stainless Steel Raw Material |

| Resistance | Corrosion Resistance |

| Efficiency (%) | 100% |

| Product Type | Sieves |

| Type | Non-Woven Filter |

| Material | Stainless Steel |

| Thickness | 6 Millimeter (mm) |

| Thermal Shrinkage | Non |

| Working Temperature | 900 Celsius (oC) |

| Application | Waste Water Filtration and Coal Fine Washing |

| FOB Port | Xingang |

| Payment Terms | Paypal, Telegraphic Transfer (T/T) |

| Supply Ability | 1000 Per Week |

| Delivery Time | 15 Days |

| Sample Available | Yes |

| Sample Policy | If order is confirmed we will reimburse the sample cost |

| Packaging Details | wooden boxes |

| Main Export Market(s) | Asia, Australia, Central America, Eastern Europe, Western Europe, Middle East, South America, North America, Africa |

| Main Domestic Market | All India |

| Certifications | ISO9001 |

Product Overview

Key Features

Processing principle and structure:

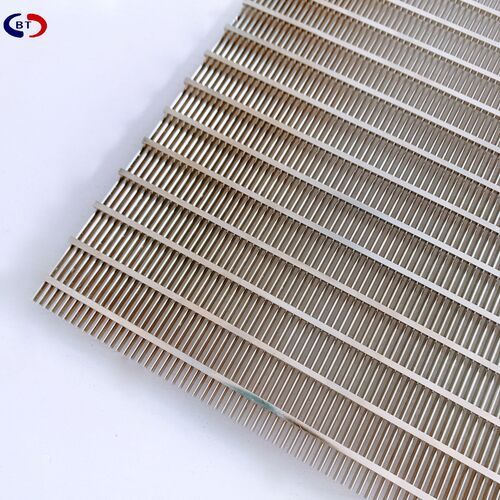

The pressure curved screen is an efficient screen that relies on pressure wet material to screen. It consists of a screen surface, a screen box, a feeding device and an outlet. The screen surface is the key component of the pressure curved screen. It is assembled by stainless steel sieve-shaped sieve bars. During operation, the wet material is sprayed from the nozzle under the pressure of 0.2-0.4Mpa. Triangular sieve wedge strips form a knife edge to scrape the material into a thin layer, so that the water and fine materials are evenly dispersed. The so-called "scraping" effect is to make the material easy to classify, and the entire screen surface is self-cleaning. The screened material is discharged from the slag outlet, and the screened material enters the slurry outlet.

Process conditions and factors affecting the screening effect:

The operating pressure is controlled between 0.2 and 0.4 MPa, and the pressure is high, the screening efficiency is high, and the production capacity is also large. If the pressure is low, the screening efficiency is also low, and the production capacity is also low. When sieving, the dry matter content of the feed is about 17%. 10-11BX, the SO2 content in the slurry should be between 0.035~0.045%.

Material: 316L or selected material.

Performance parameters:

1. The arc angle of the screen surface: 120A or selected arc

2. Screen width: 50um, 75um, 100um, 150um, 200um

3. Material handling capacity: 34~46m3/h4, feeding pressure: 0.2~0.4MPa

5. Screen width: 585mm, 710mm, 825mm

6.The arc radius of the screen surface: 762mm

7. The screen surface can be used in both directions and has a long service life.

Factors affecting screening efficiency:

1. The size of the feeding pressure. The feed pressure should be 0.2~0.4MPa. The higher the pressure, the higher the screening efficiency, and the lower the pressure, the lower the screening efficiency.

2. The arc surface of the nozzle and the sieve should be tangent. If the installation accuracy is too poor, it will not be possible to produce the cutting effect, so the screen surface will not be able to screen the material, or the movement of the material is blocked and the direction of movement is changed. At this time, the screen surface will also lose the function of screening the material.

3. The effect of the fine grinding process before the sieve: it cannot be ground too fine, otherwise the ground slag particles will enter the starch milk together with the starch granules, which will increase the slag content in the starch milk.

Company Details

Anping County BT Wire Mesh Products Co.,Ltd is a customized manufacturer and fabricator of wedge wire screen since 2003. We specialise in design and manufacturer of wedge wire flat screen, wedge wire filter, sieve bend screen, Jonhson screen pipe,Centrifuge basket etc. With more than 18 years experience in the filtration industry, we are familiar with all specific standards and the most advance testing protocols.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

100

Establishment

2009

Working Days

Monday To Saturday

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD

Related Products

Explore Related Categories

Seller Details

Anping, Hebei

Proprietor

Mr Kevin Wang

Address

Canda Industrial Park, Anping County, Hengshui City, Hebei Province, Anping, Hebei, 053600, China

wedge wire filters in Anping

Report incorrect details