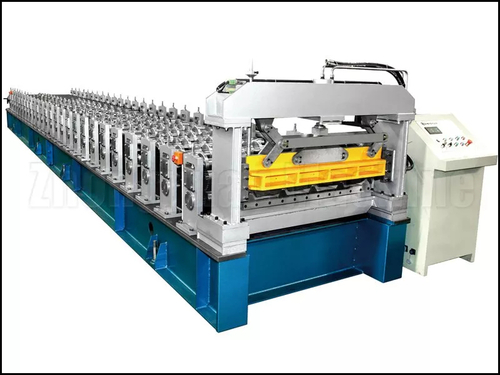

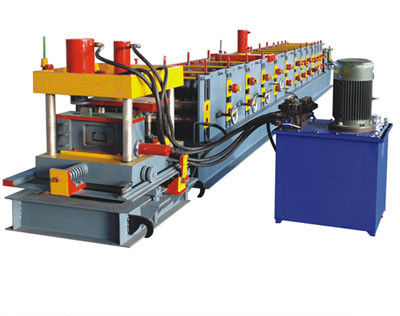

Stud Forming Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Dimensions | 7000X1000X1400Mm |

| Material | Steel Sheet |

| Thickness | 0.4-0.8Mm |

| Yield Strength | 235-345Mpa |

| Forming Speed | 15000Mm/Min |

| Power | 5.5Kw+2.2Kw |

| Control System | Mitsubishi Plc |

| Features | High Speed, Precise Cutting, Efficient Forming, Durable Design, Easy Operation, Reliable Control, Versatile Material, Cost Effective |

Product Overview

Key Features

Technical Parameters of Stud Forming Machine :-

1. Machine Dimension: About 7000mmA 1000mmA 1400mm

2. Suitable material: Galvanized Steel sheet

3. Thickness of material: 0.4-0.8mm

4. Yield strength: 235-345Mpa

5. Forming Speed: about 15000 mm/min.

6. Power Requirement : Main motor power: 5.5 Kw; Hydraulic station power: 2.2 Kw (Depend on final design)

7. Suitable Decoiler: 3000kgs(depends on customers)

8. Control system: Mitsubishi PLC and converter

9. Type of cutting: length-set cutting and post forming style

10. Electric condition: 380V/3Phase/ 50HZ or as per buyera s requirement

Material of Main Equipment

1). Roller Material: High grade No.45 forged steel, with digital-controlled procession, Surface of rollers is plated with hard chrome with thickness of 0.05mm.

2). Active Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft

3). Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan. Other elements from famous suppliers in China

4). Cutter blade: Cr12 mould steel with quenched treatment

Company Details

We are manufacturer for metal roll forming machine since 2003. Good quality and reasonable rate for our customers. 1.Zhongyuan is a from raw material to the final high-precision forming machine.All are done in our factory. Your machine quality and delivery time can be controlled here if you choose us. 2.With technical support by our 20 years experienced engineers and technicians, you can get our suggestion and solution within 24 hours. 3.You can get guarantee lifetime services for our machines. 4.Simple to install and easy to maintain. >> Our machines are well installed and tested before delivery. You only need to connect some tubes and wires in your factory. Video and manual will show you how to do. >> Our experience technicians can go to your factory and train your workers. >> We have exported 85 sets machines to India since 2008. You can trust our experience and solution for your deal between us.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

60

Establishment

2003

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Hangzhou, Zhejiang

Sales Manager

Mrs May Fu

Address

No.228, Yongli, Nanyang Street, Xiaoshan District, Hangzhou, Zhejiang, 311227, China

metal forming machines in Hangzhou

Report incorrect details