Sugarcane Baggasse Briquetting Machine Gender: Women

Price:

Get Latest Price

In Stock

Product Specifications

| Production Capacity | 1500 Kg/Hr |

| Briquette Diameter | 90 Mm |

| Briquette Shape | Cylindrical |

| Material | Steel |

| Power | Electric Motor |

| Features | High Capacity, Cylindrical Briquettes, Efficient Process, Reduced Waste, Cost Effective, High Calorific Value, Easy Operation |

Product Overview

Key Features

Sugarcane Baggasse is best raw material for briquetting as Sugarcane Baggasse is having less moisture content and size of the Sugarcane Baggasse is below 20mm so it is best for Sugarcane Baggasse Briquetting.

Sugarcane Baggasse Briquettes gives high calorific value & good thermal efficiency and leaves low ash content.

We at Radhe Engineering Co., Rajkot, Gujarat is pioneer and specialized in manufacturing Sugarcane Baggasse Briquetting Machine for converting the Sugarcane Baggasse into valuable Sugarcane Baggasse Briquettes.

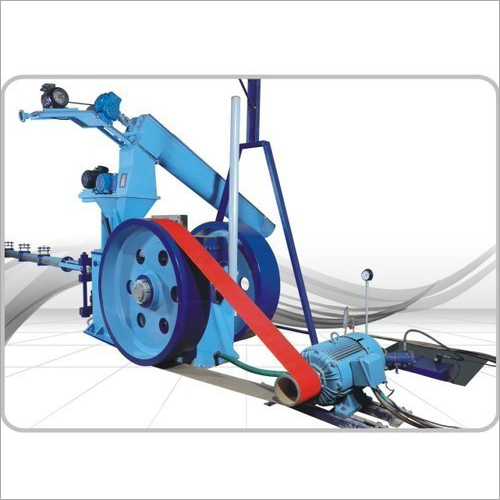

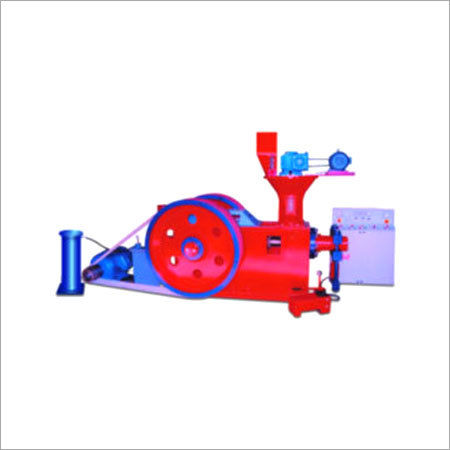

Sugarcane Baggasse Briquetting Machine a Model Jumbo 90

a cProduction Capacity:- 1500 Kgs / hr

a cFinished Product size:- 90 mm Diameter

a cFinished Product Shape:- Cylindrical

For more detail on Biomass Briquetting Project, Biomass Briquetting Machine or Sugarcane Baggasse Briquetting Machine kindly contact Radhe Engineering Co., Rajkot.

For more information on Sugarcane Baggasse Briquetting Machine contact +91-9227874035 / +91-9227874019 or email to [email protected] or visit www.radheengineering.com

For running Sugarcane Baggasse Briquetting Machine video you can visit http://www.youtube.com/watch?v=R-azJyj0cB4

Company Details

With More than 25+ Years of Domain Experiance, Radhe Engineering Co is a Pioneer & Leader in;

- Biomass Briquetting Machine

- Biomass Pellet Machine-16mm & 25mm

- Biomass Dryer - Flash Type

- Biomass Hammer Mill/Wood Dust M/C

- Biomass Drum Chipper (For Making Wood Chips).

Application: Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal).

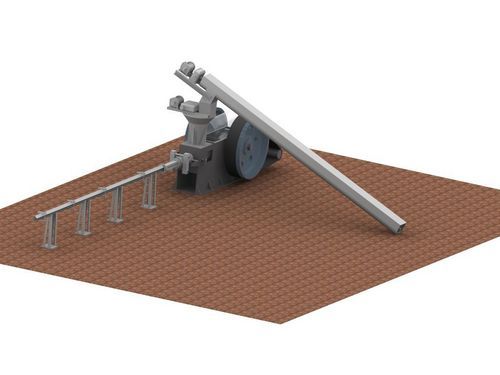

Description: The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes.

Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines.

During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology.

Super-60 Model is ideal for low production and best for waste management in agro and wood industries. If raw material ( Biomass) is available in powdery form, so this smaller model is suitable to convert Briquettes.

Features:

- Standard genuine parts with applicable MOC and process

- Compact but ideal design reference to Jumbo-90

- Temperature sensors to all bushes to prevent life of bushes.

- Auto control feeding as reference to main motor load and auto restart

- VFD to screw conveyor to change speed of feeding

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Producer

Employee Count

20

Establishment

1995

Working Days

Monday To Saturday

GST NO

24AHGPK9910L1Z3

Payment Mode

Cheque, Telegraphic Transfer (T/T), Western Union, Paypal

Certification

ISOQAR

Related Products

Explore Related Categories

Seller Details

GST - 24AHGPK9910L1Z3

Rajkot, Gujarat

Ceo

Mr Vijay C. Kalavadia

Members since

2 Years

Address

D-111, Rajdoot Industrial Estate, 5-Umakant Udyognagar, Near Mavadi Plot, Nr. Ashok Garden, Rajkot, Gujarat, 360004, India

briquetting machines in Rajkot

Report incorrect details