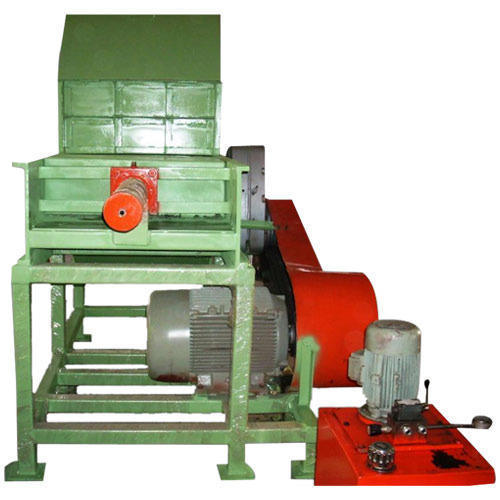

The offered Tilting Rotary Furnace is manufactured with high precision to meet the set market standards under the guidance of our deft experts with the utilization of optimum quality components and ultra-modern technology. With our immense domain expertise, we are offering quality assured range of this furnace that is used to for melting of secondary non ferrous metal extraction. In addition, we offer this Tilting Rotary Furnace in diverse technical specifications as per the demands of our patrons at reasonable prices. Features: Easy operation Robust construction Longer service life Low power consumption Design Basis Material to be processed: Zinc Maximum design temperature: 800 degree Max Operating temperature: 750 degree Furnace inside volume: 3 to 6 m3 Useful capacity of furnace: 1 to 2m3 Furnace type: Tilting Rotary with Automatic operation Fuel for furnace: FO and CNG Technical details Universal Tilting Rotary Furnace is a new generation of Rota table and tilt able melting furnace for secondary non ferrous metal extraction. This furnace is latest of its kind in the world. A significant advantage claimed for the UTRF is that it can be both rotated and tilted. First of all, the scrap is loaded in to the furnace with the smelting salt and the furnace is locked shut. By firing the burner that is mounted on door the material is heated with the help of air and oil/gas until it reaches melting point. Heating up is considerably faster resulting in saving of energy as well as melt loss. During the whole melting process, the UTRF rotates. This improves the heat transfer rate from the burner to the material, and additionally, the rotating movement promotes the separation of liquid metal from the oxide and other impurities. When all the scrap is melted, the burner can be switched off. After opening the furnace door, the liquid metal can be poured in to the holding furnace or to the other station by tilting the furnace. Through tilting the furnace even further the salt cake can be taken out. Using the UTRF enables a very high yield of material to be delivered with very low energy consumption. If compared with traditional reverbaratory furnace the yield is 2 to 5 % higher and the energy saving is to the tune of 25 to 40 %. Another significant advantage by this furnace is that metal can be recovered efficiently from the dross. This furnace is highly useful in making master alloy as during the whole melting process the furnace rotates resulting in homogenous mixing of other elements in metal. Lead Recycling EquipmentWe offer Tilting Rotary furnace / Fixed axis rotary furnace , Ingot casting and stacking line for Lead scrap recycling plants . Tilting Rotary FurnaceTilting rotary furnace is designed specifically for the processing of lead scrap. Special consideration is given for the selection of refractory to withstand high temperature.