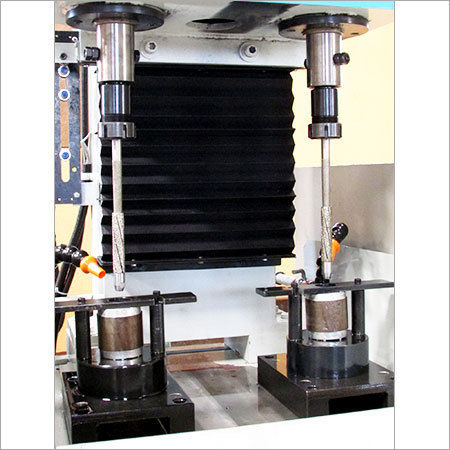

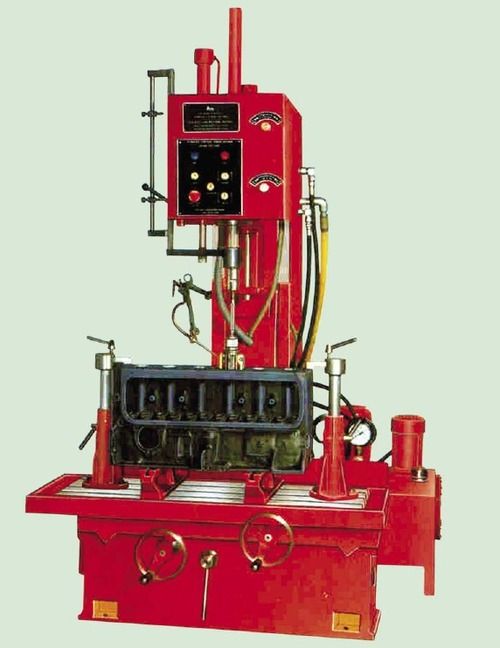

We have uniquely positioned ourselves as a dependable firm engaged in manufacturing and supplying a commendable array of Vertical Hydraulic Honing Machine. This machine is used to correct the taper & roundness and also improves the surface finish of the work piece bore. To manufacture this machine we use optimum quality mild steel sourced from trusted vendors. We offer this Vertical Hydraulic Honing Machine at cost effective prices to clients. Features: Rugged construction Noise and vibration free operation Easy to install Vertical Hydraulic Honing Machine Honing ProcessHoning process is defined that it is a method of removing the material from work piece bore by pressurizing the honing tool with reciprocating and rotation of honing tool with coolant. Honing Process is used to correct the taper roundness and improve the S. finish of the work piece bore. It is very productive process and achieves better geometrical accuracy as compared with grinding operation. Honing Machine DetailsThe machine structure is steel fabricated and machined for better accuracy. The Honing head is mounted on LM Guide ways & LM Blocks provided on machine column. The spindle is mounted in the honing head and rotated by Hydraulic Motor. Hydraulic Power Pack is provided for machine operation. The honing head reciprocation is with Hydraulic cylinder. The Expansion & Retraction of the honing tool is with Hydraulic Cylinder. Electric Panel and Control panels are attached to the machine body. The PLC is used to interface the honing machine operations. It is logically programmed with machine operations sequences and control the honing operations. HMI is used to display the running operation and to set the req. parameters. Necessary interlocks are provided. PLC is used to minimize the electric material and make compact electric panel. Proximity switches are provided to set the required length of stroke. Hydraulic valves are used to regulate the speed of Spindle rotation reciprocation of the honing head expansion and retraction of honing tool. The Machine is designed for productivity and the same time to achieve the required accuracy of the components. The various components can be honed on the same machine by replacing only honing tool and fixtures. The machine will be provided with required tooling and fixtures. Set up time is very less to reduce operator fatigue and more productivity. Machines are user friendly and very easy to operate. Special care has been taken in designing and building the m/c for smooth working and low noise level. Machine Features Machine structure is steel fabricated and machined for better accuracy. PLC and HMI is used to control and interface the machine operations. Hydraulic valves are used for spindle rotation vertical movements expansion and retraction. LM Guides and Blocks are used to run machine smoothly and low noise level. Various components can be honed on the same machine. Machine is very compact and designed for productivity and accuracy. TECHNICAL SPECIFICATIONS: Parameters Specifications/ Make Honing Range Minimum dia. 20mm. Maximum dia. 100 mm Spindle Stroke 200 mm Honing Length 200 mm Spindle & Head details No. of Spindle 1 (One) Spindle Drive Hydraulic Motor Spindle speed Hyd. Motor. Variable with hydraulic Valve. Honing Head reciprocation Hydraulic Cylinder. Reciprocation Speed Hydraulic valve. Variable by hydraulic Valve. Expansion & Retraction Hyd. Cylinder. Variable by Hydraulic valve. Honing Tool Honing Tool Expansion Internal Expansion honing. Honing tool adaption Floating type. LM Guide Ways LM Guides and Blocks Hiwin/PMI or equivalent Electrical Material Operating Voltage 415 V 3 phases 50 Hz Control Voltage 220V / 24 V PLC Delta / Omron or equivalent HMI Delta / Omron or equivalent Electric material ABB/Telemechnics/ Schneider or equivalent Other Details Lubrication System Manual Lubrication Floor Space W x B x H approx 800 x 800 x 2200mm approx. Machine Weight 1000Kgs.approx. Colour Firoja Blue & Siemens Gray/ As per req.