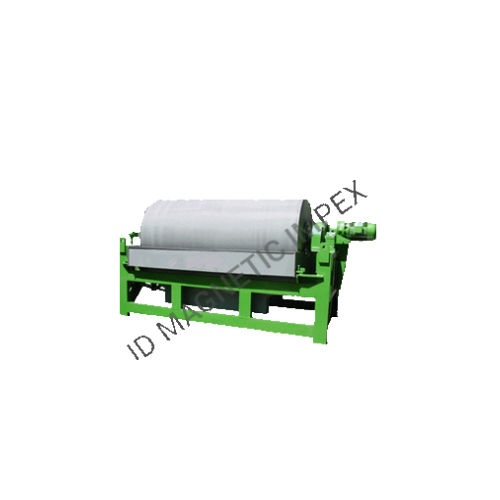

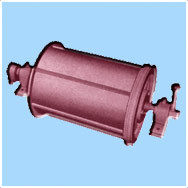

Wet Drum Magnetic Separators We manufacture Wet Drum Magnetic Separator that consists of a varied range of isotopic permanent magnets, which are placed to offer alternate polarity all across the periphery depending upon the application. Its ideal design makes it suitable for separating ferrous particles from non-ferrous materials. Moreover, it does not require electricity or a rectifier and thus is highly cost-effective. Our premium grade Wet Drum Magnetic Separator provides protection to grinders, crushers, pulverizer, and many other tools used in ore dressing or mining industry. Operating Principle The separator consists of magnet with a stainless steel 304 shell that rotates whereas the magnet remains constant. Herein, only one side of the drum is magnetized that attracts the ferrous particles during operations. As a result, ferrous particles get attracted to the one side and the non-ferrous particles get accumulated on the other side. Applications & Other Specifications Diameter And Length: Up To 1500mm With A Capacity To Handle 10 Tones. Dimension: From 300mm To600mm Industries Where Catered To: Chemical, Ceramic, Fertilizer, Glass, And Food Industry Suitable Capacities: Up To 2 tons Per Hour Selection of Magnetic Drum Clients can select a magnetic drum based on the following factors: Concentration Purification Quality of the material to be handled Size Tramp iron removal Type Type of separation Type, size and quality of ferrous combination Advantages It is designed to meet the requirement of fertilizer, food, pharmaceutical, chemical, as well as continuous process plants It is durable, cost-effective, and minimizes the breakdown chances It is highly efficient in the removal of ferrous particles from non-ferrous particles as well as crystals It renders extensive protection to grinders, crushers, and other allied equipment