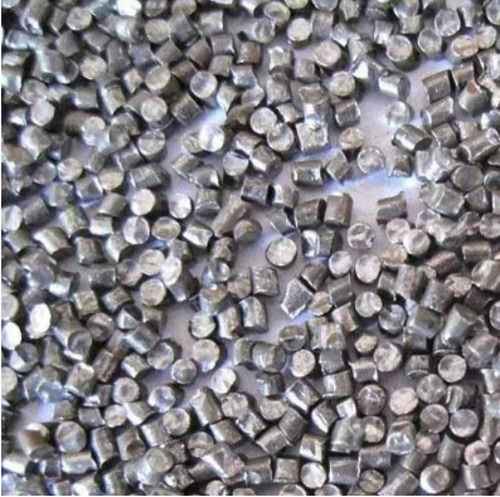

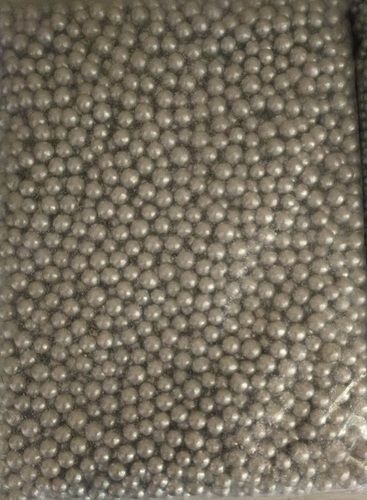

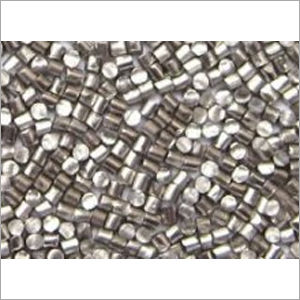

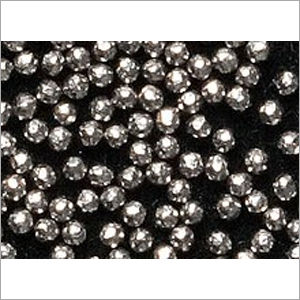

Amongst our extensive gamut of cut wire shot products, we also manufacture and supply High Carbon Cut Wire Shot to meet up the wide expectations of clients. Extensively used for peening, cleaning, tumbling and finishing applications, the offered cut wire shot is widely cherished among our clients due to its excellent finish and abrasive nature. It is manufactured by our dexterous professionals using utmost quality carbon wires that are sourced from the authentic vendors of the market. Available in various shapes, finishes and densities, the provided High Carbon Cut Wire Shot can be purchased from us at pocket friendly prices. Features: Ideal for quicker job of cleaning and blasting Minimal dust generation for cleaner surface treatment applications Efficient and faster cleaning applications Cuts down the maintenance cost of shot blasting machine ADVANTAGES OF HIGH CARBON CUT WIRE SHOT Cost effective and low consumption Consistency in shape, size and hardness Cleans the product faster Available in varied size as per requirement It increases the fatigue life of blasted components Longer life till reduced to smallest particles There is no possibility of dust formation during shot blasting Helps in cutting down maintenance cost of the shot blasting machine Assurance of no dust/ health hazard during operations Specification Grain Shape Density Hardness Packing SAE- J441 AS-CUT 7.7g/cm3 25-40 25 Kg HDPE Bag IS:5873-1970 Normal Conditioned 45-50 ISO 11124-1 Conditioned 50-55 55-60 Equivalent Sizes of High Carbon Cut Wire Shot Cast Steel Shot Size Cut Wire Shot in inches Cut Wire Shot In mm Grit Size SAE J441 Shot Size IS: 5873-1970 Shot Size Designation S-170 0.017 0.4 G-50 S-190 0.02 0.5 G-40 CW-20 S-CW50 S-230 0.023 0.6 G-40 CW-23 S-CW60 S-280 0.028 0.7 G-25 CW-28 S-CW71 S-330 0.032 0.8 G-25 CW-32 S-CW80 S-360 0.035 0.9 G-18 CW-35 S-CW90 S-390 0.041 1 G-18 CW-41 S-CW106 S-460 0.047 1.2 G-16 CW-47 S-CW118 S-550 0.054 1.4 G-17 CW-54 S-CW135 S-660 0.062 1.6 G-12 CW-62 S-CW160 S-780 0.08 2 G-10 Stainless Steel Shot Grade , Chemical Composition, and Hardness GRADE Min-Max Max Max Max Min-Max Min-Max Min-Max % % % % % % HRC 202 7.50-10.00 0.075 0.03 1 17.0-19.0 4 50-55 302 2 0.045 0.03 1 17.0 -19.0 8.0 -10.0 48-53 304 2 0.045 0.03 1 18.0 - 20.0 8.0 -10.0 48-53 430 1 0.04 0.03 1 16.0-18.0 --- 38-43