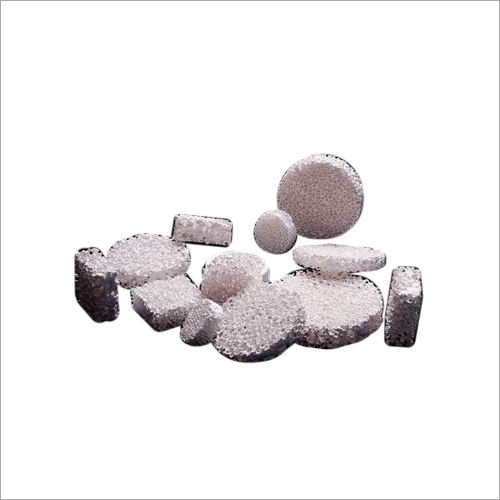

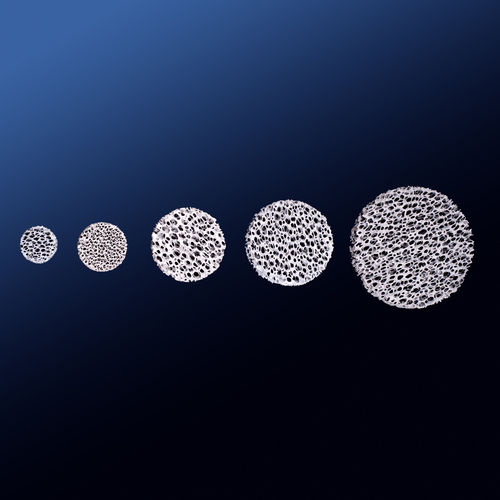

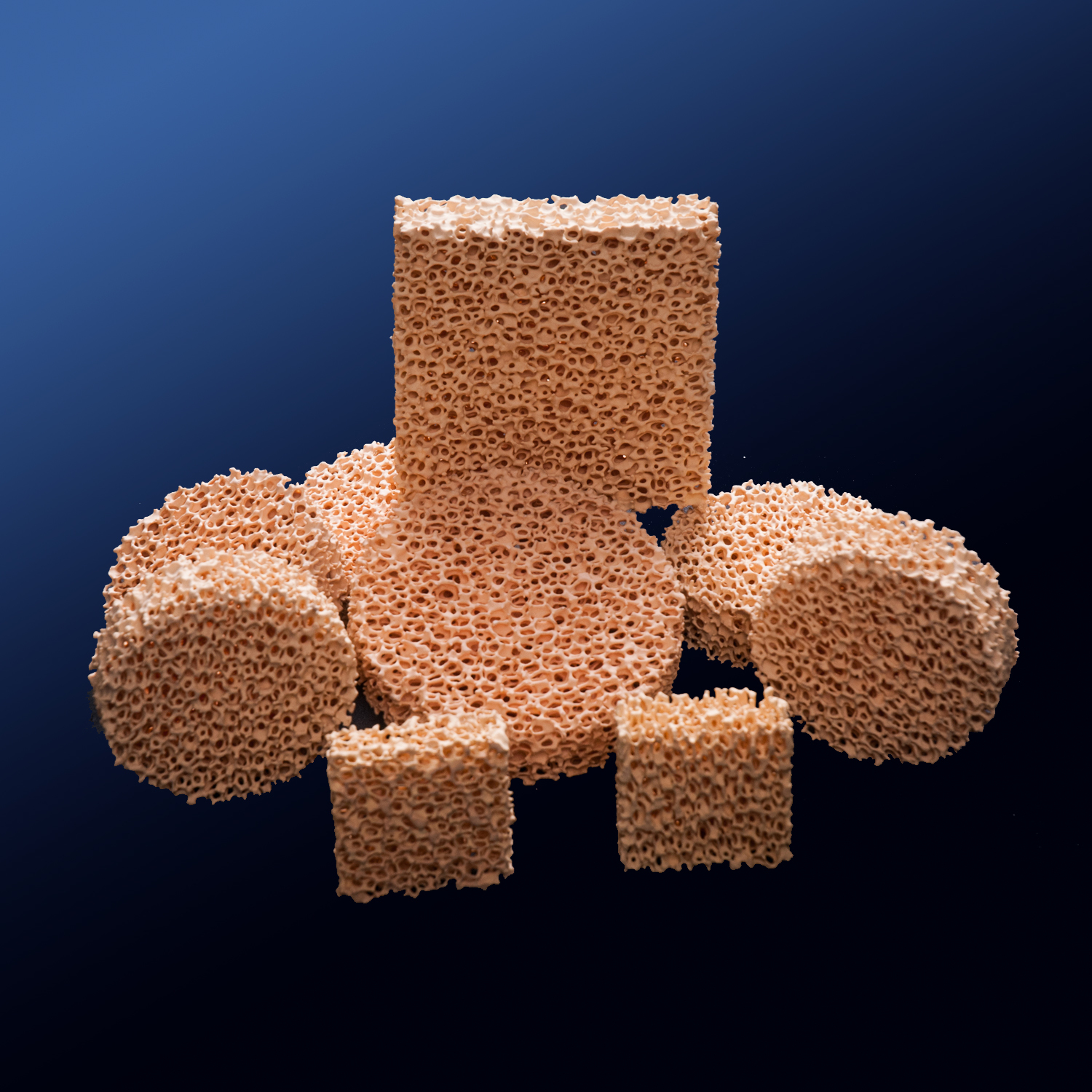

10ppi-20ppi High Quality Zirconia Ceramic Foam Filter Application: They Are Designed For Filtration Of Steel Metal Liquid

Price: null USD ($)

Get Latest Price

Minimum Order Quantity :

2000 Piece

In Stock

Product Specifications

| Height | 15-50 Millimeter (mm) |

| Efficiency (%) | 80-90% |

| Product Type | mass production |

| Color | yellow |

| Resistance | High temperature, acid and alkali resistant |

| Thickness | 15-50 Millimeter (mm) |

| Size | 40-600 |

| Type | Non-Woven Filter |

| Thermal Shrinkage | 6 |

| Weight | 50-6000 Grams (g) |

| Material | Other |

| Width | 40-500 Millimeter (mm) |

| Length | 40-600 Millimeter (mm) |

| Usage | Place the filter close to the casting |

| Capacity | 1.2 m3/hr |

| Working Temperature | 1700 Celsius (oC) |

| Application | They are designed for filtration of steel metal liquid |

| Main Export Market(s) | Africa, Australia, North America, Eastern Europe, Middle East, Western Europe, Central America, South America, Asia |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Sample Available | 1 |

| Main Domestic Market | All India |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Days after Acceptance (DA), Delivery Point (DP), Western Union, Telegraphic Transfer (T/T) |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Certifications | 2.Function They are constructed of impregnated foam in a controlled open-pore structure to provide a superior filtration effect. We provide an efficient solution for the removal of oxides and non-metallic particles from a broad range of non-ferrous metals. 3.Benefits offered *Increased Fluidity Removal of inclusions makes the metal more fluid, resulting in easier mold fill, better cast structure, and better thin section castability. *Reduced Mold and Die Wear Removal of inclusions and other nonmetallic debris from the melt reduces die soldering and mold-metal interaction, which degrades the mold surface and service life. *Longer Tool Life Oxide as well as intermetallic inclusions create a hard spotsa that damage tools in machining and finishing operations. Filtration reduces tool wear and increases productivity. *Fewer Rejects Inclusions nucleate porosity, create hot tears during solidification,cause surface defects that mar appearance, and often reduce mechanical properties. In many cases, filtration cuts rejects from such causes to virtually zero. Improvements in yield to near 100% and reduced reject rates to at or near 0% are common. Property Item Zirconia ceramic foam filter Hole density PPI 10,20ppi Bulk Density 1 Porosity 80-90% Length/OD mm 40-600 Width/OD mm 40-600 Thicknessi mmi 15-30 Working temperature a a 1700 |

| Packaging Details | carton and pallet |

| Supply Ability | 2000000 Per Year |

| Delivery Time | 15-25 Days |

| GSTIN | 0% |

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic foam filters in Cangzhou

Report incorrect details