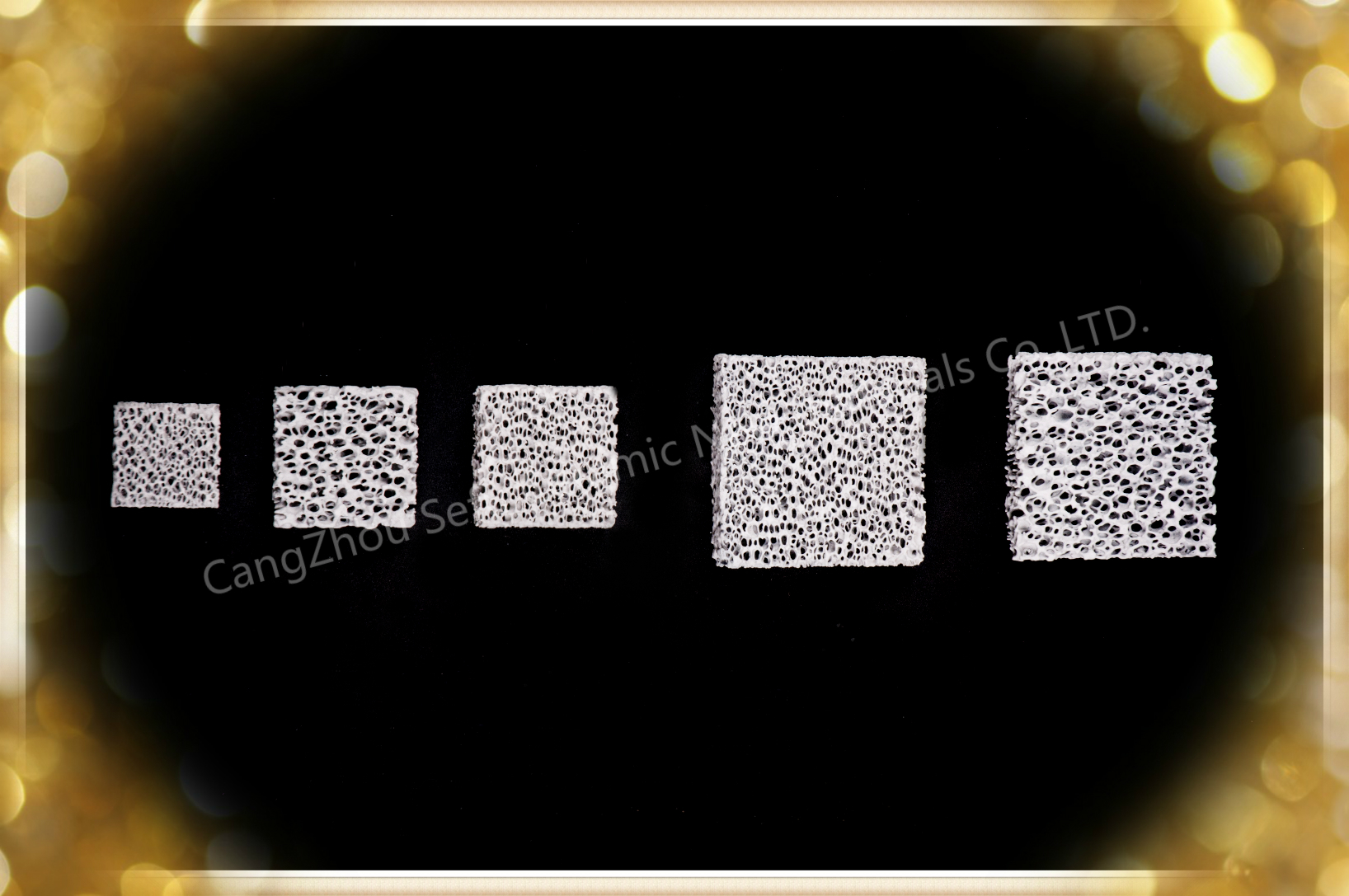

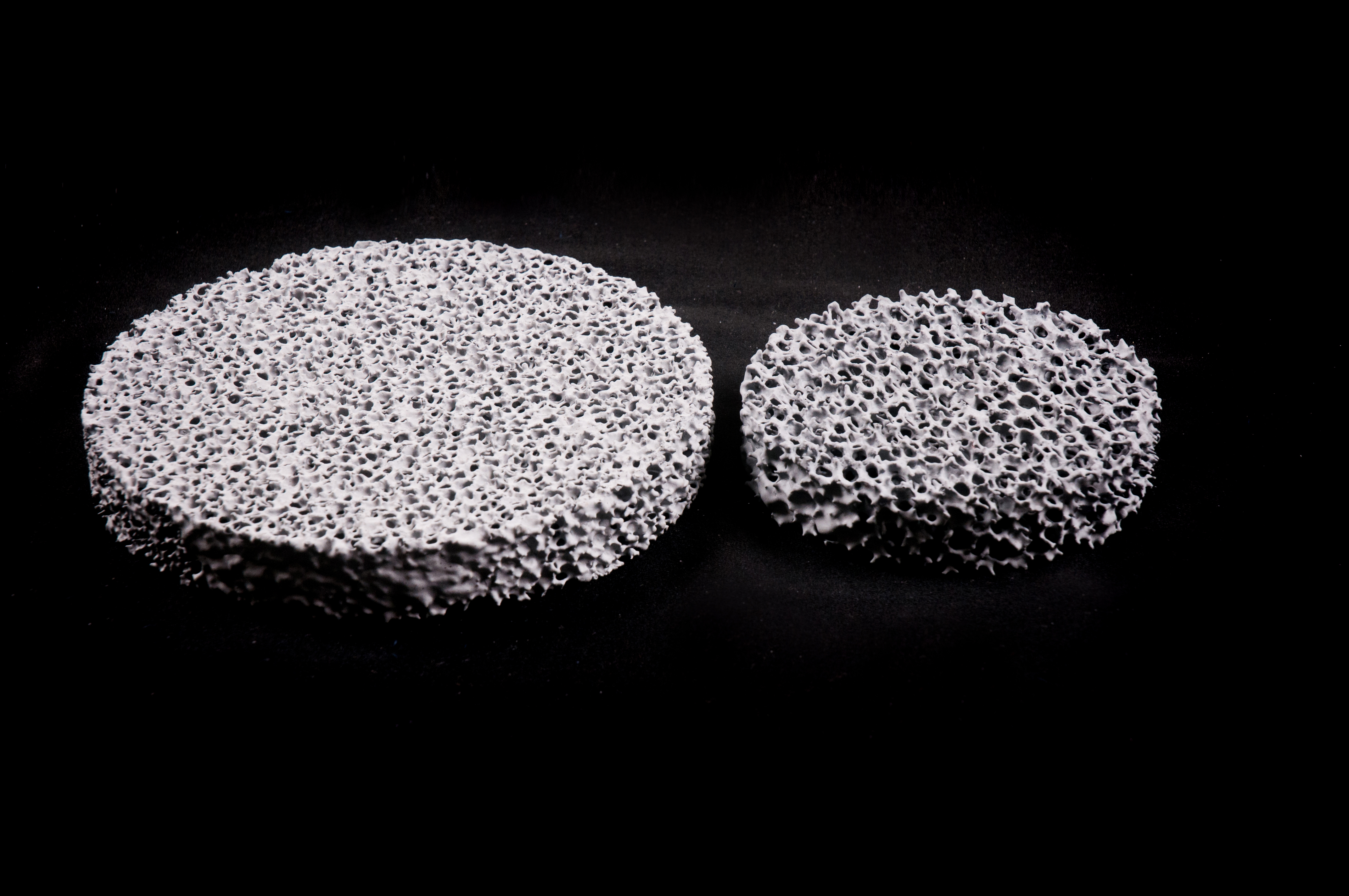

Ceramic Foam Filter Diameter: Many Kinds Millimeter (Mm)

Price Trend: 1-10 USD ($)

Get Latest Price

Minimum Order Quantity :

42 Piece

In Stock

Product Specifications

| Inlet Diameter | Multiple Specifications Millimeter (mm) |

| Material | Other |

| Product Type | SF-SIC |

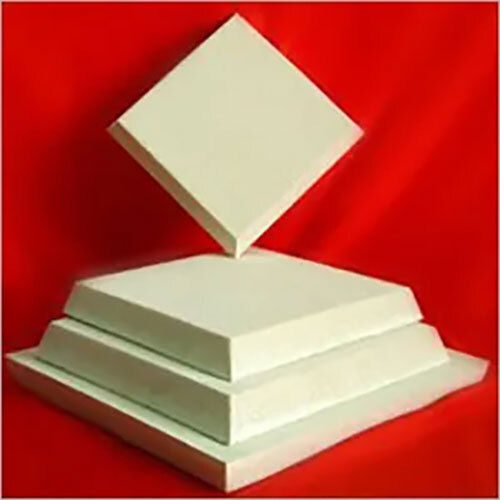

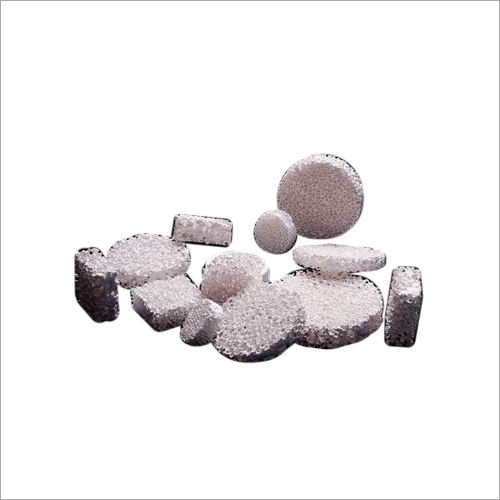

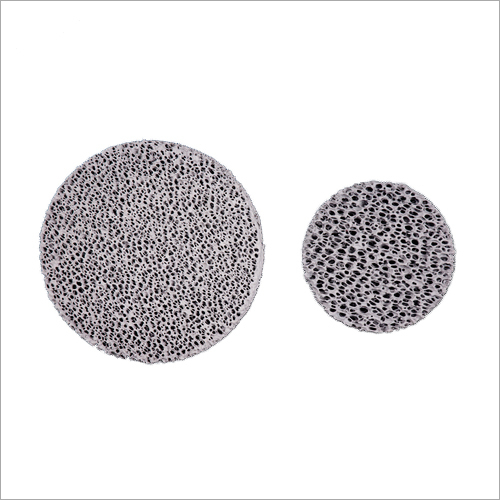

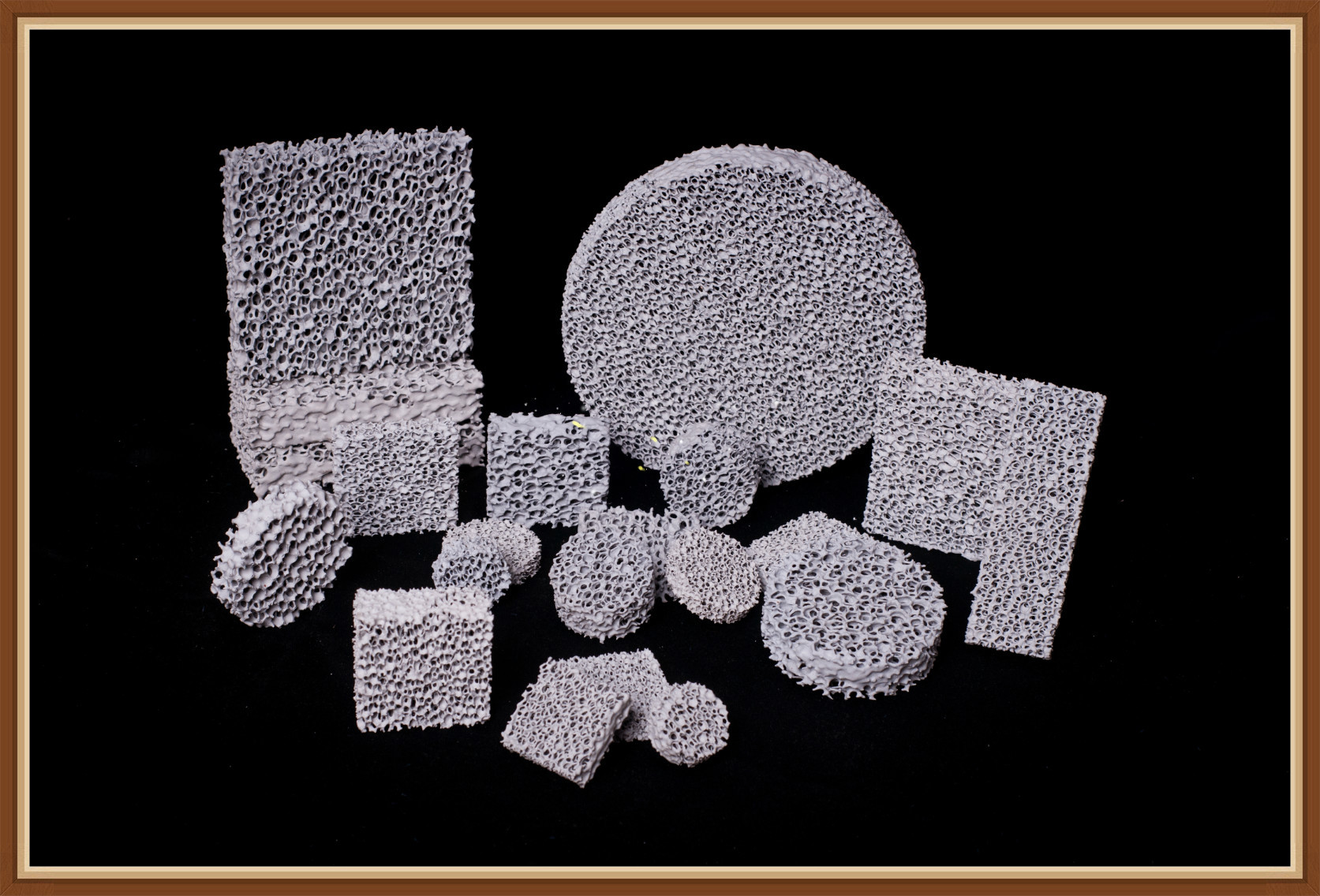

| Shape | Round ,square |

| Pressure | 0.9 mpa, 0.9 mpa |

| Outlet Diameter | Multiple Specifications Inch (in) |

| Warranty | 3years |

| Type | Specialty Filter Cartridge |

| Filter Media | Polypropylene (PP) |

| Efficiency | Very well |

| Filter Rating | 1-50kg/s |

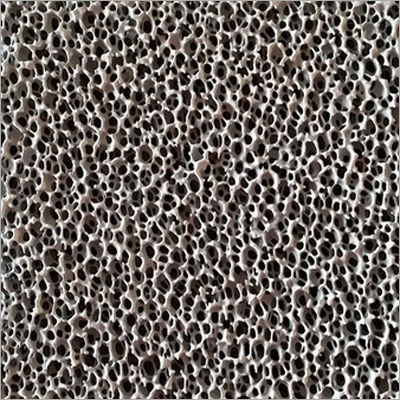

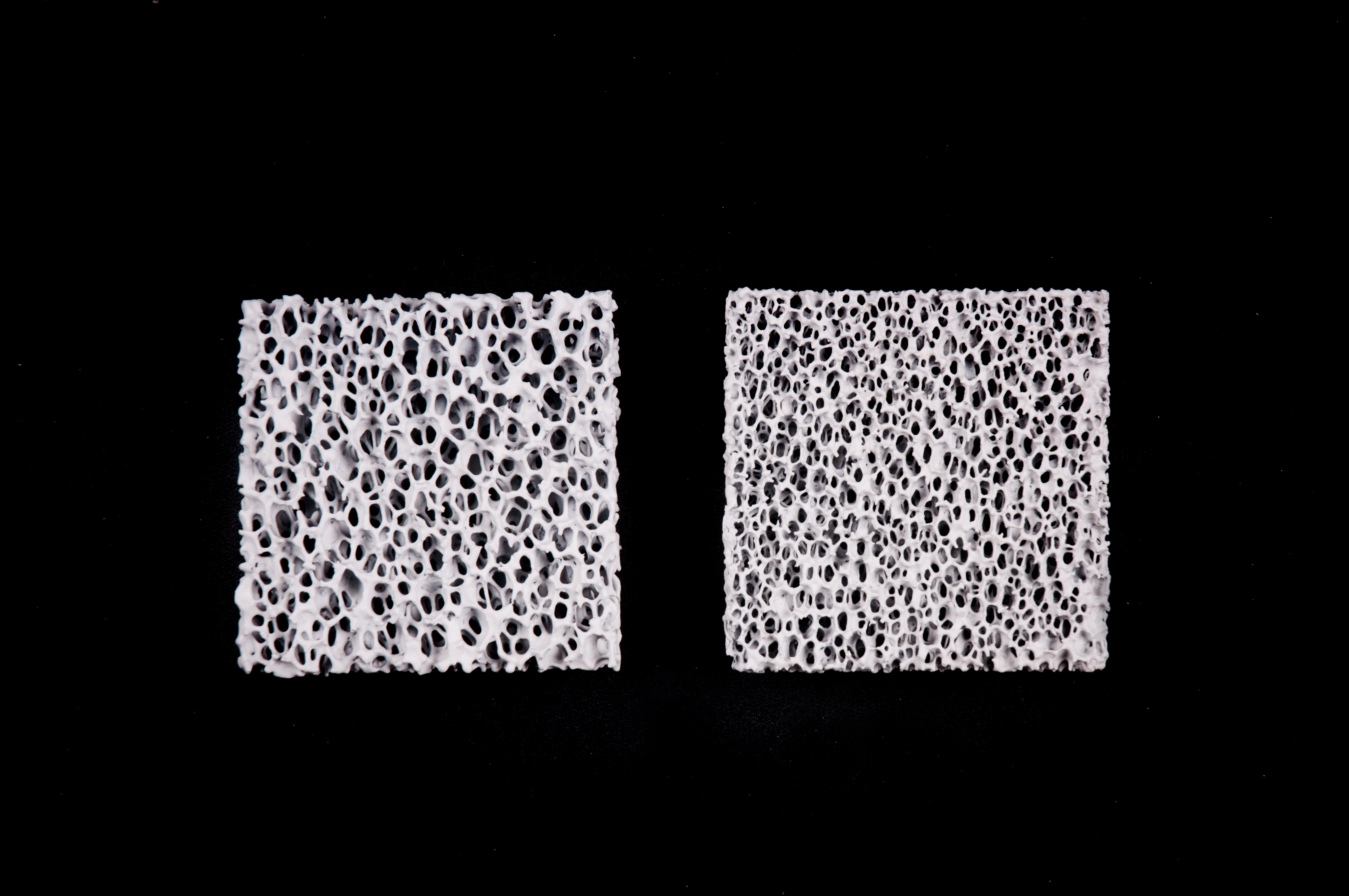

| Pore Size | 10-40 |

| Diameter | many kinds Millimeter (mm) |

| Application | in iron cassting ,water treatment ,air purification and other field |

| Cartridge Style | Double Open End |

| Sample Policy | Free samples are available |

| Delivery Time | 10-15 Days |

| Sample Available | 1 |

| Main Domestic Market | All India |

| Certifications | Pore Density (PP): 10-40 Porosity (%): 80-90 Operating temperature() : 1500 Bending Strength (MPa): 0.8 Compression Strength (MPa): 0.9 Thermal Shock Resistance(times/1100): 6 |

| Supply Ability | 4000000 Per Month |

| FOB Port | TIANJIN ,SHANGHAI ,IN CHINA |

| Packaging Details | Inside packing: Filters are put in small box and Layered packaging. There is cardboard between each layer. Outside packing: Cartons&Pallets. Three layer corrugated cartons and export special pallets . |

| GSTIN | 0% |

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic foam filters in Cangzhou

Report incorrect details