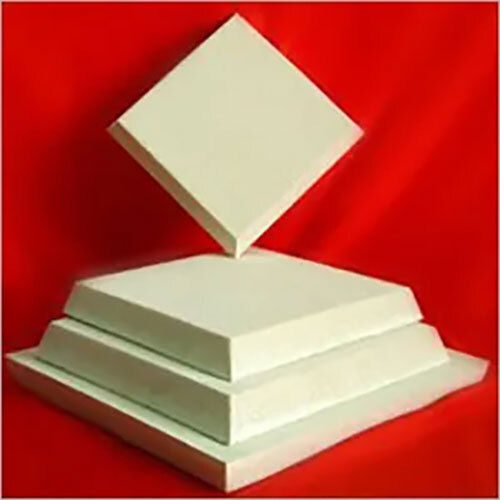

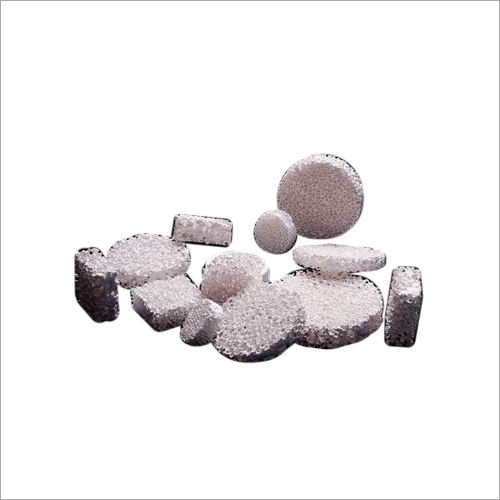

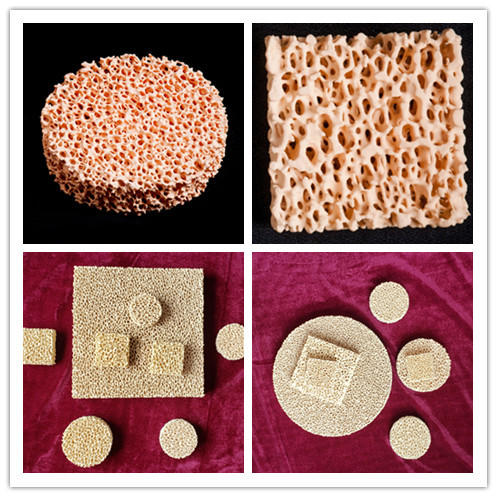

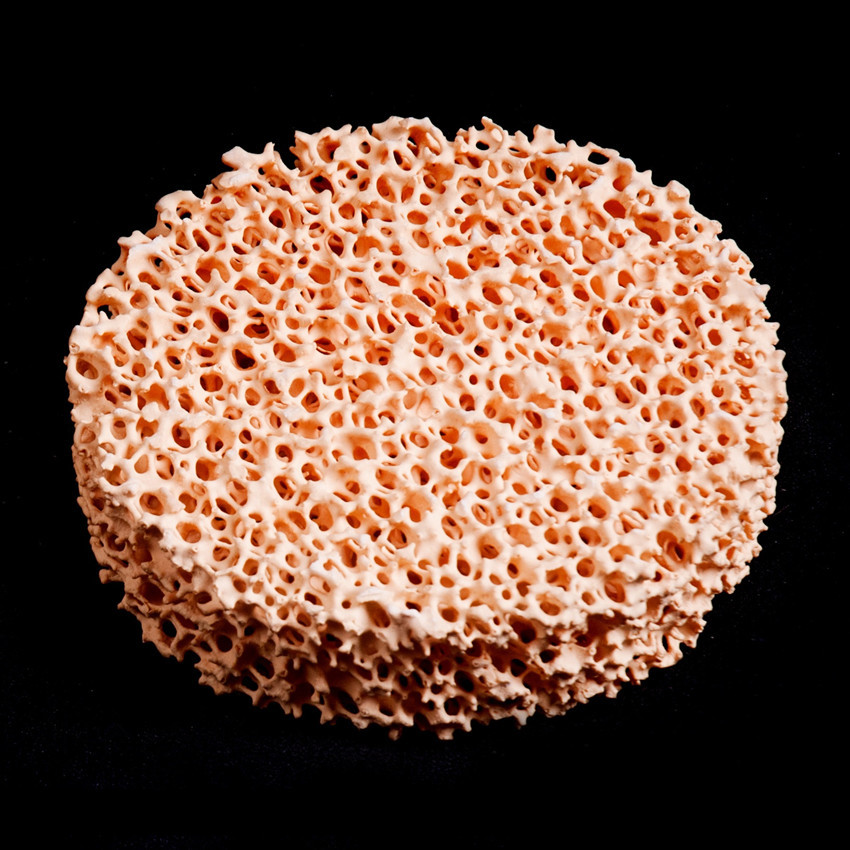

High Temperature Resistance Zirconia Ceramic Foam Filter Diameter: 40-200 Millimeter (Mm)

Price: null USD ($)

Get Latest Price

Minimum Order Quantity :

500 Piece

In Stock

Product Specifications

| Warranty | Three years |

| Product Type | mass product |

| Usage | Put the filter into sprue |

| Pressure | 1.2 kpa, 0.8 kpa |

| Diameter | 40-200 Millimeter (mm) |

| Size | 40-200 |

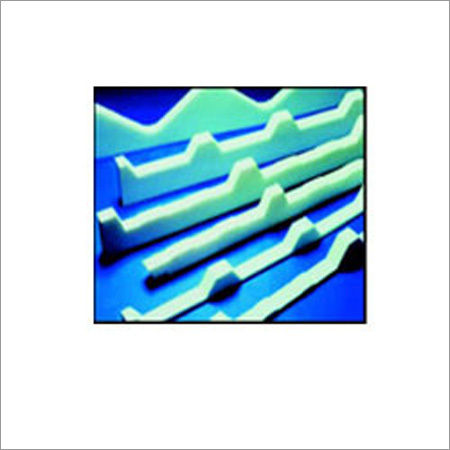

| Shape | Round ,square ,custom geometric shapes |

| Application | filter for casting |

| Filter Rating | 2-45kg/s |

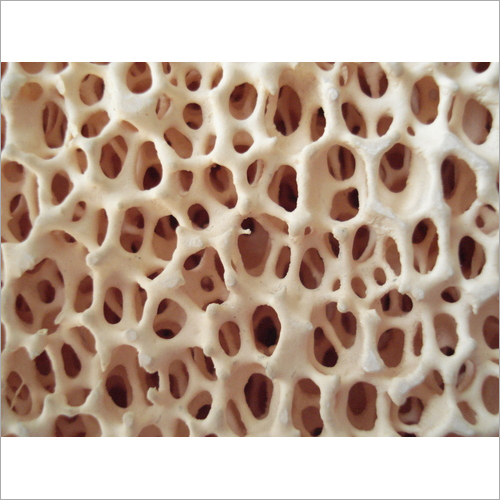

| Pore Size | 10-30ppi |

| Inlet Diameter | 30-200 Millimeter (mm) |

| Material | Other |

| Height | 40-200 Millimeter (mm) |

| Length | 40-200 Millimeter (mm) |

| Filter Media | Polypropylene (PP) |

| Cartridge Style | Double Open End |

| Width | 15-25 Millimeter (mm) |

| Efficiency | 80-90% |

| Type | Industrial Depth Filter Cartridge |

| Weight | 30-600 Grams (g) |

| Color | yellow |

| Outlet Diameter | 40-200 Millimeter (mm) |

| Main Domestic Market | All India |

| Certifications | Advantages: 1.Filter out the inclusions in the casting, reduce the gas in the casting, reduce the degree of turbulence during the flow filling of the metal, reduce the surface defects in the casting, and significantly reduce the rejection rate of the casting. 2.Improve the fluidity of molten metal, increase the filling ability and shrinkage ability of the casting, improve the surface finish of the casting, increase the compression seal of the casting, enhance the elongation and tensile strength, and improve the surface quality and mechanical properties of the casting. 3.It has very high temperature working strength, chemical stability, thermal shock resistance and resistance to metal liquid flow impact. High chemical stability makes it not affected by the acidity and alkalinity of the molten metal and does not change the chemical composition of the molten metal. There is no slag dropping or cracking in the work, which ensures the filtration quality of molten metal and the stability of chemical composition. 4.It has a large metal flow rate, and the flow rate is stable (different from the straight hole ceramic filter, the flow rate gradually decreases with the increase in the number of captured impurities). Its filtering effect is much higher than that of other filter elements. 5.It has very high dimensional accuracy and can be used in the production line for automatic filter placement Packaging and Marking: Foundry filters are packed in cardboard boxes protecting them from damage during transportation and storing.Each box has a filter identification tag containing data on: A)Filter type B)Porosity(10,20ppi) C) Dimensions D) Production date E)Production Order Number F)Number of the inspection worker G) Additional labels (Notice fragile etc.) |

| Delivery Time | 15-25 Days |

| Packaging Details | carton and pallet |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Sample Available | 1 |

| Main Export Market(s) | Australia, North America, Asia, Central America, Africa, Middle East, Western Europe, Eastern Europe, South America |

| Payment Terms | Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Western Union, Telegraphic Transfer (T/T) |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Supply Ability | 400000 Per Year |

| GSTIN | 0% |

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic foam filters in Cangzhou

Report incorrect details